Climbing plants inspire self-healing membranes

Swiss Federal Laboratories for Materials Science and Technology (Empa) researchers have been inspired by climbing plants to develop a polymer foam surface coating with a closed cell construction capable to reduce the pressure loss after the membrane is damaged. Aside making future inflatable structures more resistant, the technology could provide them with a longer operational life.

Swiss Federal Laboratories for Materials Science and Technology (Empa) researchers have been inspired by climbing plants to develop a polymer foam surface coating with a closed cell construction capable to reduce the pressure loss after the membrane is damaged. Aside making future inflatable structures more resistant, the technology could provide them with a longer operational life.

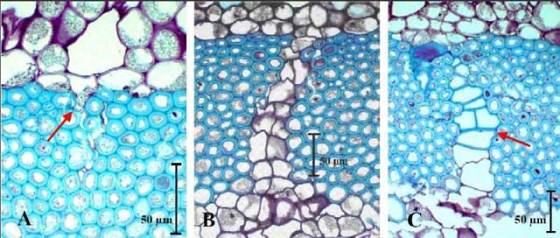

The self-healing process of the pipevine (Aristolochia macrophylla) gave a decisive clue to the biologists at the University of Freiburg, Germany. When the lignified cells of the outer supportive tissues which give the plant its bending stiffness are damaged, the plant administers “first aid” to the wound. Parenchymal cells from the underlying base tissue expand suddenly and close the lesion from the inside. Only in a later phase does the real healing process kick in and the original tissue grows back.

The same principle is applied in a bionics project sponsored by the German Federal Ministry of Education and Research. As soon as a membrane suffers damage, an additional layer provides “first aid”, thanks to its mechanical pre-tensioning, closing the hole until a proper repair can be made.

While researchers from the University of Freiburg are studying the biological and chemical aspects of the model provided by liana plants, Rolf Luchsinger and Markus Rampf at Empa’s Center for Synergetic Structures are working on technical solutions for polymer membranes. The study’s goal is to understand under which conditions a hole plugs itself up if the foam expands on a membrane following damage.

Within the scope of his dissertation, Rampf is studying this process with the help of an experimental setup which places a membrane under pneumatic pressure and then punctures it with a nail. The researchers have already achieved successful short-term results by using a two-component foam made of polyurethane and polyester. Once exposed to the excessive pressure which arises when air rushes out of a punctured hole, the material expands and fills the hole.

The current advancement of this technology could find use in air mattresses, rubber dinghies or inflatable rescue boats. The focus of Empa researchers is to develop a version suitable for tensairity beams which serve as elements for quickly erected, lightweight bridges and roofing.

For more information, you can read the article named: “Self-Repairing Membranes for Inflatable Structures Inspired by a Rapid Wound Sealing Process of Climbing Plants” (PDF).

Isn’t a similar technology used with punctured tires?

How is this innovative?