Moth-inspired anti-reflective plastics to be commercialized

Researchers from A*STAR’s Institute of Materials Research and Engineering (IMRE) and their commercial partners have developed a new plastic able to reflect between 0.09 and 0.2 percent of the visible light hitting its surface. The new plastic developed is also capable to maintain reflectivity lower than 0.7% at angles up to 45˚, thus making it better than other existing anti-reflective and anti-glare plastics in the market.

Researchers from A*STAR’s Institute of Materials Research and Engineering (IMRE) and their commercial partners have developed a new plastic able to reflect between 0.09 and 0.2 percent of the visible light hitting its surface. The new plastic developed is also capable to maintain reflectivity lower than 0.7% at angles up to 45˚, thus making it better than other existing anti-reflective and anti-glare plastics in the market.

“The new plastic was made with the unique nanoimprint expertise that we have developed at IMRE”, said Dr Low Hong Yee, senior scientist on the project who led the research. “We are also developing complementary research that allows the technology to be easily scaled-up to an industrial scale.”

Nanoimprinting involves engineering of the physical aspects of materials rather than using strong and harmful chemicals to achieve the desired effect. The technology allows creation of nanometer-sized structures with greater complexity using fewer processing steps, while minimizing wastage of materials.

It has evolved from a lithography technology for the semiconductor industry to a platform process technology that can be adapted to a wide range of applications. This plastic material is the first successful result of the IMRE-led Industrial Consortium On Nanoimprint (ICON), which partners local and overseas companies to promote the manufacturing of nanoimprint technology.

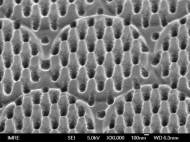

Unlike production of other similar plastics, the technology developed at IMRE has allowed the researchers to create complex hierarchical ‘moth eye-like’ anti-reflective structures whose ability to diffuse light inspired Fraunhofer Institute researchers to come up with their non-reflecting surfaces. Nanometer-sized structures are placed on top of other microstructures, thus creating special patterns that are better at reducing glare and reflection, while providing wider viewing angles compared to currently available plastics.

The first project in ICON on the topic on anti-reflection was launched in August 2010 in collaboration with A*STAR’s Institute of High Performance Computing (IHPC), DSO National Laboratories, and it has support from companies such as Innox Co., Ltd., Solves Innovative Technology Pte Ltd, NTT- Advanced Technology Corporation, Nypro, Inc., and Young Chang Chemical Co., Ltd.

The plastics developed by IMRE could be used for various applications, ranging from TV displays to windows and even solar cells. TV viewers can have wider viewing angles and it is even more suitable for use with gadgets we tend to carry along and protect from the sun when its glare doesn’t allow us to see the desired information. These anti-reflective surfaces could also prove useful for organic solar cells, where they could be used to provide improved light absorption.

Leave your response!