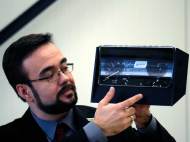

Moths inspire perfectly non-reflecting surfaces for displays

Inspired by moths, the research scientists at the Fraunhofer Institute for Mechanics of Materials IWM, Freiburg, developed a new nanocoating that ensures a perfectly non-reflecting view on displays and through eyeglasses. The necessary surface structure is applied to the polymeric parts during manufacture, obviating the need for a separate process step. The hybrid coating also makes surfaces scratch-proof and easy to clean.

Inspired by moths, the research scientists at the Fraunhofer Institute for Mechanics of Materials IWM, Freiburg, developed a new nanocoating that ensures a perfectly non-reflecting view on displays and through eyeglasses. The necessary surface structure is applied to the polymeric parts during manufacture, obviating the need for a separate process step. The hybrid coating also makes surfaces scratch-proof and easy to clean.

Since moths have to hide from predators, they search for food at dusk. While most of the other insect’s eyes shimmer, the moth’s eyes are perfectly non-reflecting. It is possible due to tiny protuberances smaller than the wavelength of light which form a periodic structure on the surface. This nanostructure creates a gentle transition between the refractive indices of the air and the cornea, providing the reduction in reflection of light and enabling moth to remain undetected.

Researchers have adopted this natural ability and adapted it to a range of different applications. Whereas conventional methods apply the anti-reflective coating in a separate step after production, the Fraunhofer scientists have found a way of reducing light reflection during actual manufacture of the part or component: “We have modified conventional injection molding in such a way that the desired nanostructure is imparted to the surface during the process,” explained Dr. Frank Burmeister, project manager at the IWM.

In order to achieve that, the researchers have developed a hard material coating which reproduces the optically effective surface structure. “We use this to coat the molding tools,” said Burmeister. “When the viscous polymer melt is injected into the mold, the nanostructures are transferred directly to the component.” Because no second process step is required, manufacturers achieve an enormous cost saving and also increase efficiency. “Normally the component would have to undergo an additional separate process to apply the anti-reflex coating,” Burmeister adds.

Normal plexiglass and some anti-reflex coatings are particularly sensitive, but the scientists are producing wipe-resistant and scratch-proof surfaces. For this purpose the injection mold is additionally flooded with an ultra-thin organic substance made of polyurethane. The substance runs into every gap and hardens, like a two-component adhesive. The result is an extremely thin nanocoating of polyurethane on which the optically effective surface structures, which are just one ten-thousandth of a millimeter thick, are also reproduced.

Working in cooperation with industrial partners, the research scientists aim to develop components for the auto industry because the material is not only attractive but it’s also hard-wearing and easy to clean. The technology could be easily applied on eyeglasses, cell phone displays, fitting or panel covers, and other transparent surfaces which are useful only if they allow viewing without light reflecting back.

Leave your response!