Nature inspires a new multifunctional glass surface

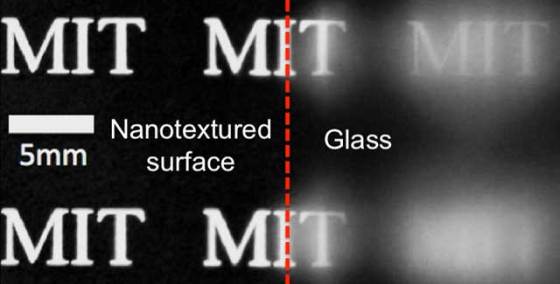

Inspired by nature, where textured surfaces ranging from lotus leaves to desert-beetle carapaces and moth eyes have developed in ways that often fulfill multiple purposes at once, a group of researchers from MIT developed a glass that is self-cleaning, virtually eliminates reflections, and resists fogging and glare. These features could lower the maintenance expenses for solar farms, and the researchers hope that it will be more widely used along with its lowered cost in future.

Inspired by nature, where textured surfaces ranging from lotus leaves to desert-beetle carapaces and moth eyes have developed in ways that often fulfill multiple purposes at once, a group of researchers from MIT developed a glass that is self-cleaning, virtually eliminates reflections, and resists fogging and glare. These features could lower the maintenance expenses for solar farms, and the researchers hope that it will be more widely used along with its lowered cost in future.

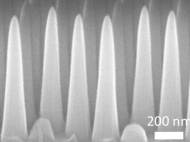

Instead treating solar panels with hydrophobic coatings, the new glass surface conceived by the MIT researchers does prevent reflective losses, giving the new system advantage over other water repelling and self-cleaning surfaces. The new glass owes its multifunctionalily to its surface nanotextures that produce an array of conical features. The surface pattern consists of an array of nanoscale cones that are five times as tall as their base width of 200 nm.

Although the arrays of pointed nanocones on the surface appear fragile when viewed microscopically, the researchers claim that the material should be resistant to a wide range of forces, ranging from impact by raindrops in a strong downpour or wind-driven pollen and grit to direct poking with a finger.

The patent pending fabrication process relies on coating and etching techniques adapted from the semiconductor industry. The glass surface is coated with several thin layers, including a photoresist layer, which is then illuminated with a grid pattern and etched successively to produce the conical shapes.

The researchers plan to test how these nanotextured surfaces prove to hold up over time in practical applications, the researchers plan to increase the efficiency of its fabrication by simply passing the transparent polymer films through a pair of textured rollers while still partially molten.

The researchers hope that an inexpensive manufacturing process could be used to produce glass for optical devices such as microscopes and cameras, the screens of smartphones and televisions, solar panels, as well as car windshields where the surface could be used to clean the dirt and grit on the exterior surface, eliminate glare and reflections, and prevent fogging on the interior surface.

According to researchers, photovoltaic panels can lose up to 40 percent of their efficiency within six months as dust and dirt accumulate on their surfaces. Aside the need for self-cleaning surfaces that would lower the maintenance costs, there’s a need for supertransmissive materials able to transmit the light through their surface, rather than reflecting them away. For example, when the sun’s rays hit the panel surface at a sharp angle, conventional glass can reflect away more than 50 percent of the light.

For more information, read the paper published in the journal ACS Nano: “Nanotextured Silica Surfaces with Robust Super-Hydrophobicity and Omnidirectional Broadband Super-Transmissivity”.

The paper is co-authored by MIT’s Department of Engineering graduate students Kyoo-Chul Park and Hyungryul Choi, former MIT postdoc Chih-Hao Chang SM ’04, PhD ’08 (now at North Carolina State University), chemical engineering professor Robert Cohen, and mechanical engineering professors Gareth McKinley and George Barbastathis.

Leave your response!