Nature inspires faster battery charging

A multidisciplinary team of researchers from the Karlsruhe Institute of Technology (KIT) has been inspired by the way water is transported in trees and they used the same physicochemical effect to develop a faster way to fill the porous electrodes of lithium-ion batteries with liquid electrolyte. Aside lowering the time needed for battery consumption, the process enables creation of more efficient batteries.

A multidisciplinary team of researchers from the Karlsruhe Institute of Technology (KIT) has been inspired by the way water is transported in trees and they used the same physicochemical effect to develop a faster way to fill the porous electrodes of lithium-ion batteries with liquid electrolyte. Aside lowering the time needed for battery consumption, the process enables creation of more efficient batteries.

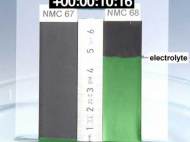

The electrodes inside modern batteries are porous which causes creation of larger surface areas needed to be covered by liquid electrolyte which acts as a transport medium during the chemical processes such as electric charge or discharge. However, the materials used in conventional high-energy batteries for automotive industry show poor wetting of the electrode surface by the liquid electrolyte.

“But the pores have to be filled completely with the electrolyte for optimized operation”, said Dr. Wilhelm Pfleging from KIT. “Without electrolyte, there is no charge equalization inside and no electric current flow outside.”

In order to solve that problem, most of the battery producers turn to time-consuming and costly process which involves filling the electrolyte into the smallest pores by vacuum or storage processes at high temperatures. The process developed by KIT researchers allows the process to be sped up from several hours down to a few minutes.

With use of mechanochemical technology (coupling of the mechanical and the chemical phenomena on a molecular scale), the electrodes are modified in a way that allows the electrolyte to be sucked into the battery in a way similar to water being sucked into high trees. The electrolyte spreads very rapidly over the complete material, thus lowering the time needed for production and increasing performance of batteries.

“This novel electrode modification drastically reduces the technical expenditure and production times needed for filling lithium-ion cells with electrolyte”, said Andreas Gutsch, coordinator of Competence E project which involves more than 250 scientists at KIT. “Now, an interdisciplinary team of physicists, chemists, materials researchers, and process engineers has succeeded in making an important step towards low-cost batteries.”

Since the technology allows higher efficiency, it could lead to faster charging batteries which are suitable for future electric vehicles. The researchers have already applied for a patent, and they hope that it will be integrated in production lines of battery manufacturers as quickly as possible.

Leave your response!