New bioinspired artificial lung is efficient enough to operate on air

An artificial lung built by researchers from Case Western Reserve University uses air instead pure oxygen which is required by current man-made lungs require. The researchers built the prototype device by following the natural lung’s design and tiny dimensions. Unfortunately, the commercial use of their invention is still years away, but the device is a major step toward creating an easily portable and implantable artificial lung.

An artificial lung built by researchers from Case Western Reserve University uses air instead pure oxygen which is required by current man-made lungs require. The researchers built the prototype device by following the natural lung’s design and tiny dimensions. Unfortunately, the commercial use of their invention is still years away, but the device is a major step toward creating an easily portable and implantable artificial lung.

Current artificial lung systems require heavy tanks of oxygen, limiting their portability. Due to their inefficient oxygen exchange, they can be used only on patients at rest, and the lifetime of the system is measured in days. Those facts focused Case Western Reserve University researchers on improving efficiency and portability of artificial ling systems.

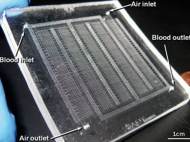

The researchers first built a mould with miniature features and then layered on a liquid silicone rubber that solidified into artificial capillaries and alveoli, and separated the air and blood channels with a gas diffusion membrane. The artificial lung is filled with breathable silicone rubber versions of blood vessels that branch down to a diameter less than one-fourth the diameter of human hair.

“Based on current device performance, we estimate that a unit that could be used in humans would be about 6 inches by 6 inches by 4 inches tall, or about the volume of the human lung. In addition, the device could be driven by the heart and would not require a mechanical pump”, said lead researcher Joe Potkay, a research assistant professor in electrical engineering and computer science at Case Western Reserve University.

By making the parts on the same scale as the natural lung, the team was able to create a very large surface-area-to-volume ratio and shrink the distances for gas diffusion. Tests using pig blood show oxygen exchange efficiency is three to five times better, which enables them to use plain air instead of pure oxygen as the ventilating gas.

Potkay’s team is now collaborating with researchers from Case Western Reserve’s departments of biomedical engineering and chemical engineering to develop a coating to prevent clogging in the narrow artificial capillaries and on construction techniques needed to build a durable artificial lung large enough to test in rodent models of lung disease.

Within a decade, the group expects to have human-scale artificial lungs in use in clinical trials. They envision patients would tap into the devices while allowing their own diseased lungs to heal, or maybe implant one as a bridge while awaiting a lung transplant.

For more information, you can read the article published in the journal Lab on a Chip named: “Bio-inspired, efficient, artificial lung employing air as the ventilating gas”.

Leave your response!