Novel bio-inks can be used to print various types of tissue

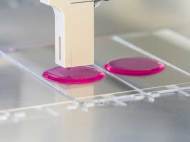

A group of researchers at the Fraunhofer Institute have succeeded in developing bio-inks for tissue printing technology. The transparent liquids consist of components from the natural tissue matrix and living cells, such as a well known biological material – gelatin. By controlling the chemical modification of this biomolecule, researchers can imitate the properties of various natural tissue types.

A group of researchers at the Fraunhofer Institute have succeeded in developing bio-inks for tissue printing technology. The transparent liquids consist of components from the natural tissue matrix and living cells, such as a well known biological material – gelatin. By controlling the chemical modification of this biomolecule, researchers can imitate the properties of various natural tissue types.

Gelatin is derived from collagen that is the main constituent of natural tissue. Fraunhofer Institute for Interfacial Engineering and Biotechnology (Fraunhofer IGB) researchers have chemically modified the gelling behavior of the gelatin in order to adapt the biological molecules for printing. Unlike unmodified gelatin, the bio-inks remain fluid during printing. Only after they are irradiated with ultraviolet (UV) light, they crosslink and cure to form hydrogels.

The bio-inks are polymers containing a huge amount of water like native tissue, but these molecules are stable in aqueous environments as well as when being warmed up to physiological 37°C (98.6°F). The researchers can control the chemical modification of the biological molecules so that the resulting gels have differing strengths and swelling characteristics. The properties of natural tissue can therefore be imitated – from solid cartilage to soft adipose tissue.

“We are concentrating at the moment on the ‘natural’ variant. That way we remain very close to the original material. Even if the potential for synthetic hydrogels is big, we still need to learn a fair amount about the interactions between the artificial substances and cells or natural tissue”, said Kirsten Borchers, professor at Fraunhofer IGB. “Our biomolecule-based variants provide the cells with a natural environment instead, and therefore can promote the self-organizing behavior of the printed cells to form a functional tissue model.”

The printers at the labs have a lot in common with conventional office printers because the ink reservoirs and jets are all the same. The differences can be found in the heater on the ink container which sets the right temperature of the bio-inks. Also, the number of jets and tanks is smaller compared to the office counterpart.

“We would like to increase the number of these in cooperation with industry and other Fraunhofer Institutes in order to simultaneously print using various inks with different cells and matrices. This way we can come closer to replicating complex structures and different types of tissue”, said Borchers.

The big challenge at the moment is to produce vascularized tissue – a tissue that has its own system of blood vessels through which the tissue can be provided with nutrients. Fraunhofer IGB scientists are working on this jointly with other partners under Project ArtiVasc 3D. The core of this project is development of a technology platform that generates fine blood vessels from synthetic materials. It could be used to create for artificial skin with its subcutaneous adipose tissue.

“This step is very important for printing tissue or entire organs in the future. Only once we are successful in producing tissue that can be nourished through a system of blood vessels can printing larger tissue structures become feasible”, said Borchers.

Leave your response!