Researchers getting closer to creation of 3D printed blood vessels

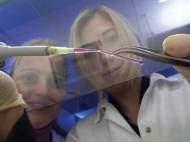

Researchers at Fraunhofer are combining two different techniques – 3D printing technology established in rapid prototyping and multiphoton polymerization developed in polymer science – in order to create artificial blood vessels. Aside creating artificial blood vessels that could be used to could supply artificial tissue, the technology could be a starting point for creation of higher complexity organs.

Researchers at Fraunhofer are combining two different techniques – 3D printing technology established in rapid prototyping and multiphoton polymerization developed in polymer science – in order to create artificial blood vessels. Aside creating artificial blood vessels that could be used to could supply artificial tissue, the technology could be a starting point for creation of higher complexity organs.

A 3D printer can generate 3D objects from a wide variety of materials very quickly. It applies the material in layers of defined shape and these layers are chemically bonded by UV radiation. Although the technology is capable to create microstructures, it is still too imprecise for creation of the fine structures such as capillary vessels. This is why the researchers combined this technology with two-photon polymerization.

Brief and intensive laser impulses impact the material and stimulate the molecules in a very small focus point. Due to the properties of the precursor molecules that have been adjusted by the chemists in the project team, a crosslinking of the molecules occurs and the material becomes an elastic solid. This process increases the precision of the elastic structures created according to the 3D model.

The blood vessels have to be flexible and elastic and interact with the natural tissue. Therefore, the synthetic tubes are biofunctionalized in a way that suits the living body cells. Modified biomolecules (such as heparin and anchor peptides) are integrated into the inside walls. They also develop inks made of hybrid materials that contain a mixture of synthetic polymers and biomolecules right from the beginning.

The second step is where endothelial cells that form the innermost wall layer of each vessel in the body can attach themselves in the tube systems. The vessel can only work in the same fashion as its natural model to direct nutrients to their destination if we can establish an entire layer of living cells.

“The individual techniques are already functioning and they are presently working in the test phase; the prototype for the combined system is being built”, said Dr. Günter Tovar, the project manager at the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB based in Stuttgart. “We are establishing a basis for applying rapid prototyping to elastic and organic biomaterials. The vascular systems illustrate very dramatically what opportunities this technology has to offer, but that’s definitely not the only thing possible.”

Due to complexity of these structures and variations in course of the vascular systems we won’t be seeing this technology applied on humans in near future, but it offers a starting point for future production of designed 3D shaped biomaterials. Once the technology advances, it could enable creation of artificial organs based on a circulation system with artificially created blood vessels used to supply them with nutrients.

They are exhibiting their findings at the Biotechnica Fair that will be taking place in Hannover, Germany on October 11-13.

Leave your response!