Sea shells inspired a new material made of chalk and polystyrene

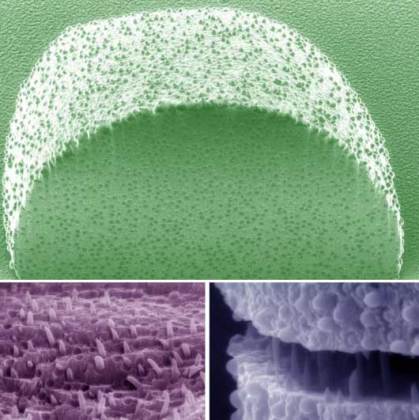

A team of materials scientists and chemists from The University of Manchester and The University of Leeds have taken inspiration from sea shells found on the beach to create a composite material from dissimilar ‘ingredients’. They have successfully reinforced calcium carbonate, or chalk, with polystyrene particles that are used to make drinks cups. They report that the polystyrene also acts as a toughening agent, assisting the prevention of the growth of cracks.

A team of materials scientists and chemists from The University of Manchester and The University of Leeds have taken inspiration from sea shells found on the beach to create a composite material from dissimilar ‘ingredients’. They have successfully reinforced calcium carbonate, or chalk, with polystyrene particles that are used to make drinks cups. They report that the polystyrene also acts as a toughening agent, assisting the prevention of the growth of cracks.

Calcium carbonate is the main ingredient of chalk, which is very brittle and breaks easily when force is applied. But shells are strong and resistant to fracturing, and this is because the calcium carbonate is combined with proteins which bind the crystals together, like bricks in a wall, to make the material stronger and sometimes tougher. They have developed an effective method of combining calcite crystals with polystyrene particles which makes the material more ductile compared to its original brittle form.

Dr Stephen Eichhorn from The School of Materials at The University of Manchester, conducted the experiments in collaboration with Professor Fiona Meldrum in the School of Chemistry at the University of Leeds, where they observed that when the reinforced material cracked, the polymer lengthened within the cracks thus acting as a well-known mechanism for absorbing energy and enhancing toughness. Researchers say their method allows the properties of the new material to be tweaked by selecting particles of different shapes, sizes and composition.

“The mechanical properties of shells can rival those of man-made ceramics, which are engineered at high temperatures and pressures. Their construction helps to distribute stress over the structure and control the spread of cracks”, Eichhorn said. “Further research and testing is still needed but our research potentially offers a straightforward method of engineering new and tough chalk-based composite materials with a wide range of useful applications.”

Their technique could be used to make ceramics with high resistance to cracking thus ensuring its usage in crack-resistant building materials and bone replacements.

Another perfect adoption from Nature.

Dr.A.Jagadeesh Nellore(AP),India