Spider hairs biomimicry for hydrophobic surfaces

Although we already wrote about lotus biomimicry for water-repelling surfaces, in this article we’re going to write about a surface with similar properties. Engineering researchers have created what they say is a “nearly perfect hydrophobic interface” by mimicking spiders. By using plastic to reproduce the shape and patterns of the minute hairs that grow on the bodies of spiders, the researchers have created one of the most water-phobic surfaces yet.

Although we already wrote about lotus biomimicry for water-repelling surfaces, in this article we’re going to write about a surface with similar properties. Engineering researchers have created what they say is a “nearly perfect hydrophobic interface” by mimicking spiders. By using plastic to reproduce the shape and patterns of the minute hairs that grow on the bodies of spiders, the researchers have created one of the most water-phobic surfaces yet.

Wolfgang Sigmund, a professor of materials science and engineering at the University of Florida (UF), began working on the project about five years ago after picking up on the work of a colleague. He was experimenting with microscopic fibers when he turned to spiders, noted by biologists for at least a century for their water-repelling hairs. Spiders use these hairs to stay dry or avoid drowning, with water spiders capturing air bubbles and toting them underwater to breathe.

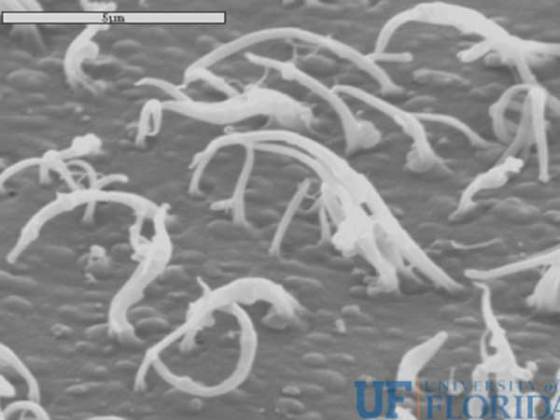

Sigmund says initially he made all his fibers the same size and distance apart. But he learned that spider hairs are both long and short and variously curved and straight, forming a surface that is anything but uniform. He decided to try to mimic this random, chaotic surface using plastic hairs varying in size but averaging about 600 microns, or millionths of a meter. The result was the ultra-water repellent surface.

“Most people that publish in this field always go for these perfect structures, and we are the first to show that the bad ones are the better ones,” Sigmund said. “Of course this is a finding in a lab. This is not something you expect from theory.”

Close-up photographs of water droplets on dime-sized plastic squares show that the droplets maintain their spherical shape, whether standing still or moving. Droplets bulge down on most other surfaces, dragging a kind of tail as they move. Sigmund said his surface is the first to shuttle droplets with no tail.

The surface works equally well with hot or cold water and Sigmund says a variation of the surface also repels oil, a first for the industry. Making the water or oil-repelling surfaces involves applying a hole-filled membrane to a polymer, heating the two, and then peeling off the membrane. Made gooey by the heat, the polymer comes out of the holes in the desired thin, randomly sized fibers.

While inexpensive, it is hard to produce successful surfaces with great reliability, and different techniques need to be developed to make the surfaces in commercially available quantities and size, Sigmund said. Also, he said, more research is needed to make the surfaces hardy and resistant to damage.

The potential applications for the ultra-water-repellent surface are food packaging, or windows, or solar cells that must stay clean to gather sunlight. It would also be possible for boat designers to coat hulls with it for faster, more efficient boats.

Leave your response!