Using fungi to create more environmentally friendly alternative to some plastics

Fungi, with the exception of mushrooms we find tasty at some point of their lifetime, tend to be something we associate with moldy bread and stench. Fungal colonies composed of mycelia are found in soil and on or within many other substrates. Researchers at Union College are cooperating with Ecovative Design to use mycelia to create environmentally-friendly products.

Fungi, with the exception of mushrooms we find tasty at some point of their lifetime, tend to be something we associate with moldy bread and stench. Fungal colonies composed of mycelia are found in soil and on or within many other substrates. Researchers at Union College are cooperating with Ecovative Design to use mycelia to create environmentally-friendly products.

Mycelia, mostly underground portion of fungi, are a tiny biological chain of tubular cells. A mycelium can be small, forming a colony that is too minute to see, or it can form one of the largest organisms in the known world. A site in eastern Oregon had a contiguous growth of mycelium before logging roads cut through it. Estimated at 1,665 football fields in size and 2,200 years old, this one fungus killed the forest above it several times over, and it managed to build deeper soil layers that allow the growth of ever-larger stands of trees.

“It’s this linked chain of cells that’s able to communicate with the outside world, to sense what’s there in terms of food and light and moisture. Mycelia can take in nutrients from available organic materials like wood and use them as food, and the fungus is able to grow as a result”, said Steve Horton, Union College Biology Professor. “When you think of fungi and their mycelia, their function – ecologically – is really vital in degrading and breaking things down. Without fungi, and bacteria, we’d be I don’t know how many meters deep in waste, both plant matter and animal tissue.”

Ecovative Design, in Green Island, N.Y., is harnessing this particular mycological power and is being helped by Horton and Ronald Bucinell, associate professor of mechanical engineering at Union Colege. They are using several species of fungi to manufacture environmentally-friendly products.

The process itself lasts a bit less than five days, and it starts with farming byproducts, such as cotton gin waste, seed hulls from rice, buckwheat and oats, hemp or other plant materials. These materials are sterilized, mixed with nutrients and chilled. In the next step, mycelia spawn are added to the mix. Mycelia multiply so good that every cubic inch of material soon contains millions of tiny fungal fibers.

This compact matrix is then grown in a mold the shape of whatever item Ecovative is making. Once the desired texture, rigidity and other characteristics of the product are achieved, it’s popped from its mold, heated and dried to kill the mycelia and stop its growth.

Final products are completely non-toxic and haven’t exhibited allergy concerns. To a point, the materials are also impervious to fire. Aside being as water resistant as Styrofoam, these materials are also more UV-stable than foam since they are not petrochemical-based. This means that these materials won’t emit volatile organic compounds. When exposed to the right microbes, they will break down in 180 days in any landfill or backyard.

Mycelium is comparatively inexpensive too as it can grow on farm waste that can’t be fed to animals or burned for fuel. Better yet, the fungi can be propagated without sunlight or much human oversight in simple trays at room temperature – thus leading to smaller carbon footprint. Ecovative is hoping to the point where they can displace all plastics and foams in the market.

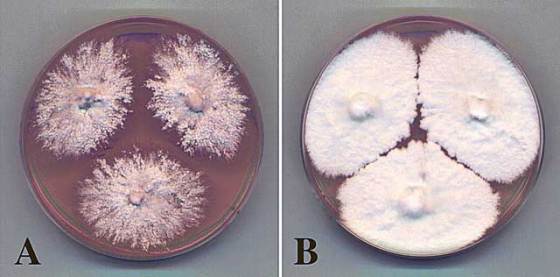

Union researchers are aiding them in this effort by altering the species of fungus Ecovative uses in its manufacturing. They manipulate on strain various ways to create a version that can be used for certain applications or accelerate the process by growing faster.

Leave your response!