Brother Incorporated improve their Retinal Imaging Display

In our previous article where we wrote about NEC Retinal Imaging Display, we announced we’re going to write about several other examples of that technology. Brother Industries, Ltd, a company actively working on Retinal Imaging Display (RID) technology, announced that they succeeded in development of a mobile prototype. RID is a projection technology that focuses light, of an intensity harmless to the eyes, onto the retina and then moves the light at high speed to create afterimages. Images projected onto the retina appear as if they existed in front of the user.

In our previous article where we wrote about NEC Retinal Imaging Display, we announced we’re going to write about several other examples of that technology. Brother Industries, Ltd, a company actively working on Retinal Imaging Display (RID) technology, announced that they succeeded in development of a mobile prototype. RID is a projection technology that focuses light, of an intensity harmless to the eyes, onto the retina and then moves the light at high speed to create afterimages. Images projected onto the retina appear as if they existed in front of the user.

Brother Industries developed the RID by applying optical system technologies based on their laser printing technology, and piezoelectric technologies based on their ink-jet printing technology. The device enables you to see a transparent display of RID images without affecting the visual field, giving the impression of a 16 square inch screen viewed 1 meter ahead.

That provides users an opportunity to view private images and confidential data anywhere. Unlike the developers from NEC, these guys noted they developed this system in order to enable users to read documents such as operation manuals at the narrow spaces, or to be hands-free when they want to use both hands.

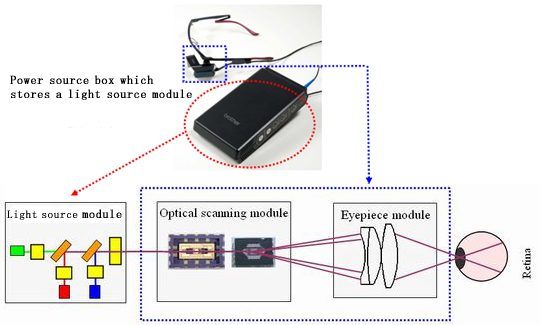

Brother created an attraction for demonstrating a stationary type RID at EXPO 2005 in Aichi, Japan. In 2008, Brother succeeded in developing a spectacle-type wearable RID prototype. The newest prototype clears the conventional assignment of practical application by downsizing a power source box which stores light source modules. Its size is approx. 95×170×30mm and it weights only 350g. The system consists of three modules: a light source module, an optical scanning module, and an eyepiece module.

Light source module requires laser light sources of the light’s three primary colors: red, green and blue, to view images in full color. Brother used a green solid state laser for the previous prototypes since a green laser diode was not in practical use. Therefore, it was difficult to downsize the light source module and this was a big hurdle for the commercialization. However, Brother succeeded in downsizing the light source module by adopting a green laser diode for the first time in the world. It is able to show SVGA resolution (800×600) with a 60Hz frame rate.

An optical scanning module and an eyepiece module were already downsized by applying optical scanning system technologies based on the laser printing technologies. Brother has been developing piezoelectric MEMS technologies based on its ink-jet printing technology. With this technology, it successfully developed in-house an optical MEMS scanner (high-speed scanning mirror device), with world-class operating frequency, to create clear images.

Leave your response!