Fast laser lithography 3D printing on the micrometer scale

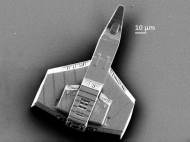

A spin-off company of Karlsruhe Institute of Technology (KIT) named Nanoscribe GmbH recently presented their 3D printer able to print microstructures. Based on a laser lithography method, the 3D printer can create minute 3D objects that are smaller than the diameter of a human hair. What’s great about this 3D printer is its ability to print faster than its competition while maintaining maximum resolution.

A spin-off company of Karlsruhe Institute of Technology (KIT) named Nanoscribe GmbH recently presented their 3D printer able to print microstructures. Based on a laser lithography method, the 3D printer can create minute 3D objects that are smaller than the diameter of a human hair. What’s great about this 3D printer is its ability to print faster than its competition while maintaining maximum resolution.

“The success of Nanoscribe is an example of KIT’s excellent entrepreneurial culture and confirms our strategy of specifically supporting spin-offs. In this way, research results are transferred rapidly and sustainably to the market”, said Dr. Peter Fritz, KIT Vice President for Research and Innovation.

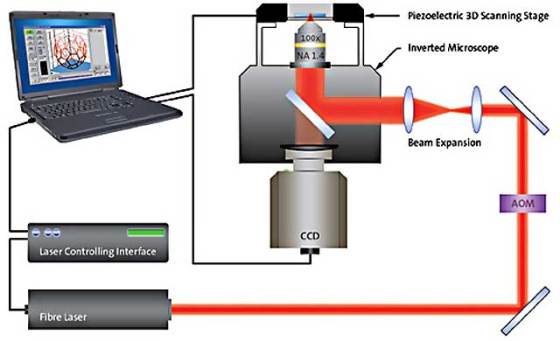

So, how does it work? The direct laser writing technique used for 3D printing is based on two-photon polymerization. Ultra-short laser pulses polymerize photosensitive materials in the laser focus in a way similar to focused rays of sunlight burn paper after going though a magnifying glass. Depending on the chosen photosensitive material, the exposed or unexposed volume becomes more prone to dissolving. So, after a bath of the photosensitive material is applied, these written (or unwritten) areas remain as self-supporting microstructures.

Dubbed galvo technology, the approach enables rapid creation of 3D microstructures on relatively large areas. This laser lithography method for 3D printing uses a galvanic mirror system, a technology that is also applied in laser show devices or scanning units of CD and DVD drives. Nanoscribe propriety directlaser writing (DLW) process enables an accurate coordination of beam deflection, sample movement and laser intensity modulation even at high writing speeds. A control system consisting of matched optics, electronics and software has been developed in close collaboration with Nanoscribe’s suppliers.

Nanoscribe came up with new version of their 3D printer named Photonic Professional GT, and it has improved piezoelectric scanning stage provides ultra-precise x-y-z-movements of the substrate relative to the laser focus position. The table-top laser lithography systems are fully automated and it relies on user-friendly software with Nanoscribe´s GWL scripting language. The printer can also be used with 3D compatible CAD software programs.

Reflecting a laser beam off the rotating galvo mirrors aids rapid and precise laser focus positioning. Compared to previous methods, printing speed is increased by factor of about 100. This speed advantage literally turns minutes into seconds.

At highest resolution, however, the scanning field is limited physically to a few 100 µm due to the optical properties of the focusing objective to ensure the seamless connection of layers. On the other hand, writing area of this Photonic Professional GT 3D printer is up to a centimeter range.

“We are revolutionizing 3D printing on the micrometer scale. Precision and speed are achieved by the industrially established galvo technology. Our product benefits from more than one decade of experience in photonics, the key technology of the 21st century”, said Martin Hermatschweiler, the managing director of Nanoscribe GmbH.

Work in the area of photonics concentrates on replacing conventional electronics by optical circuits of higher performance. For this purpose, Nanoscribe systems are used to print polymer waveguides reaching data transfer rates of more than 5 terabits per second.

This approach could prove very practical in biosciences where it could be used to produce tailored scaffolds for cell growth studies. In materials research, 3D printing at micro- and nano-size could enable development of functional materials with enhanced performance.

Leave your response!