New affordable microcamera could improve future endoscopes

Advancements in technology have enabled microcameras on the tip of endoscopes to supply images from the inside of the human body in ever higher resolution, which often makes it possible to identify tumors at an early stage. In order to counter the downsides such as costs and the time consuming procedure of sterilization between uses, researchers from Fraunhofer University came up with inexpensive, small and disposable (degradable) microcameras.

Advancements in technology have enabled microcameras on the tip of endoscopes to supply images from the inside of the human body in ever higher resolution, which often makes it possible to identify tumors at an early stage. In order to counter the downsides such as costs and the time consuming procedure of sterilization between uses, researchers from Fraunhofer University came up with inexpensive, small and disposable (degradable) microcameras.

Digital camera systems basically consist of two components – a lens and a sensor that transforms the image into electrical signals. Electrical contacts on the sensor allow access to these signals and therefore also to the information of the image. Due to the way they are manufactured, these contacts are located between the sensor and the lens. The sensors are manufactured simultaneously in large numbers, like computer chips. About 28,000 image sensors fit onto one wafer and until recently, each and every one was sawed out, wired and mounted on the lens that was still missing.

The new microcamera is being developed in cooperation of the Fraunhofer Institute for Reliability and Microintegration (IZM) in Berlin, Germany with Awaiba GmbH and with the support of the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena, Germany.

“You have to think of a book full of postage stamps where many thousand stamps are printed in one step. If you want to use them, you have to separate one from another. Instead of a sheet of paper, with image sensors you have a circular disc of silicon that is known as a wafer”, said Martin Wilke, a scientist at the Fraunhofer Institute for Reliability and Microintegration.

The researchers at the Fraunhofer Institute for Reliability and Microintegration have streamlined this process by developing a new way to access the electrical contacts. By using their method, they simultaneously reach the contacts of each image sensor via their reverse side while they are still connected as a wafer, rather than reaching the contacts of each individual image sensor via their side. After that process is completed, the stack of wafers sawed apart into individual microcameras.

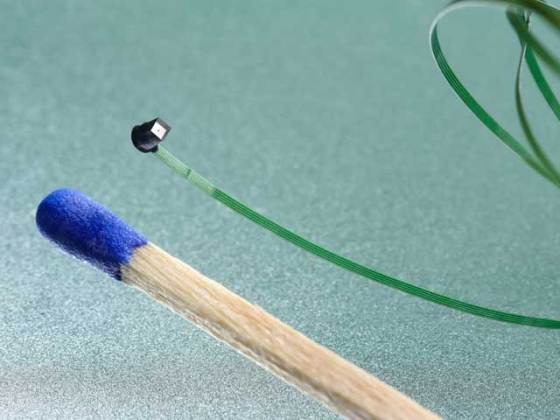

To date, the camera systems built into endoscopes had to be separate because of their size. The lens was at the tip of the endoscope and the sensor at the other end of the glass fiber strand. The new microcamera is small enough to fit the tip of the endoscope. It has a resolution of 62,500 pixels and transmits the image information through the endoscope via an electrical cable. Stephan Voltz, the CEO of Awaiba GmbH, claims that their camera is the smallest he’s aware of because its size is 1 cubic millimeter.

“Starting in 2012, using Fraunhofer’s expertise, we will be able to bring disposable endoscopes to market for only a few euros – we already have the prototype”, said Voltz.

Aside medical applications, the researchers mentioned the potential of this technology in the automotive industry where it could replace outside rearview mirrors on cars with microcameras. This would reduce flow resistance and energy consumption. Beyond this, installed in fittings, this camera would be able to calculate the driver’s eye movements and prevent him from nodding off for a few seconds.

Leave your response!