Top 5 articles regarding technology in 2012

Alongside the usual news and articles about breakthroughs in energy storage and generation, there were many breakthroughs in materials science and biomedicine during the last year. Development of 3D chips is gaining its momentum, and there are many attempts to utilize low-value materials that were usually discarded after some other production process, as well as to increase our quality of life.

Alongside the usual news and articles about breakthroughs in energy storage and generation, there were many breakthroughs in materials science and biomedicine during the last year. Development of 3D chips is gaining its momentum, and there are many attempts to utilize low-value materials that were usually discarded after some other production process, as well as to increase our quality of life.

These are the 5 most read technology news and articles that were published in 2012:

5. Using 3D printing technology to restore China’s artifacts

Funded by the Chinese Government, Loughborough University researchers are using the latest 3D digital technologies to restore the former glory of the Palace Museum in Beijing – a place better known as the Forbidden City. They employ laser and optical scanners to record the shape of the original objects and clean up the acquired data by using reverse engineering techniques. Once this process is completed, the data of digitally restored relics and artifacts can be used in the 3D printing process.

Funded by the Chinese Government, Loughborough University researchers are using the latest 3D digital technologies to restore the former glory of the Palace Museum in Beijing – a place better known as the Forbidden City. They employ laser and optical scanners to record the shape of the original objects and clean up the acquired data by using reverse engineering techniques. Once this process is completed, the data of digitally restored relics and artifacts can be used in the 3D printing process.

Although the mentioned methodology for restoration has been available for a while now, Loughborough University researchers are defining a formalized approach suitable for the restoration of historic artifacts. The process has already been applied to a range of objects from the Forbidden City and elsewhere.

4. Major breakthrough for iron-air batteries

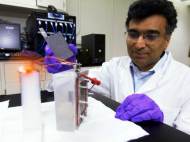

A team of researchers from University of Southern California (USC) developed an air-breathing battery that uses the chemical energy generated by the oxidation of iron plates that are exposed to the oxygen in the air. Iron-air batteries saw a surge in interest during the 1970s energy crisis, but a competing chemical reaction of hydrogen generation that takes place inside the battery (known as hydrolysis) wasted about 50 percent of the battery’s energy.

A team of researchers from University of Southern California (USC) developed an air-breathing battery that uses the chemical energy generated by the oxidation of iron plates that are exposed to the oxygen in the air. Iron-air batteries saw a surge in interest during the 1970s energy crisis, but a competing chemical reaction of hydrogen generation that takes place inside the battery (known as hydrolysis) wasted about 50 percent of the battery’s energy.

USC researchers managed to reduce the energy loss down to 4 percent, making iron-air batteries that are about 10 times more efficient than their predecessors. The team developed batteries with the capacity to store 8-24 hours worth of energy, a high charging-efficiency of 96%, a high discharge capacity of 0.3 Ah/g, and also a twenty-fold increase in capacity for the two-hour discharge rate. Tests performed by the researchers shown that the efficiency and discharge performance were stable with repeated cycling. Due to their weight, these batteries could be used to store energy generated by solar or wind power.

3. More environmentally friendly and less costly cement developed

Two separate research groups have applied two different approaches to improve cement in order to make it more durable and greener. Researchers from the Michigan State University have found that mixing ground waste glass into the cement makes resulting concrete stronger, more durable and more resistant to water, while Drexel University researchers found a way to lower its cost and make it more environmentally friendly.

Two separate research groups have applied two different approaches to improve cement in order to make it more durable and greener. Researchers from the Michigan State University have found that mixing ground waste glass into the cement makes resulting concrete stronger, more durable and more resistant to water, while Drexel University researchers found a way to lower its cost and make it more environmentally friendly.

About 20 percent of the cement that is used to produce the concrete is replaced by milled, or finely ground, glass. The resulting concrete is a little lighter in color, but the difference is mostly indistinguishable. Contrary to cement, the lower temperatures needed to process milled glass significantly reduce the amount of energy used, as well as CO2 emissions. The process is also beneficial because it reduces the amount of glass that ends up in landfills.

Researchers from Drexel University used a different approach by improving ordinary Portland cement (OPC) to make it more energy efficient and cost effective to produce. Drexel’s “green” variety is a form of alkali-activated cement that utilizes an industrial byproduct, called slag, and a common mineral, limestone, and does not require heating to produce. This alternative production method lessens the cost of materials needed to create cement by about 40 percent, and it reduces energy consumption and carbon dioxide production by 97 percent.

2. Battery 500 Project – IBM’s lithium-air battery development

IBM Research started the Battery 500 Project to develop lithium-air battery technology that could be used to power a family-sized electric car for approximately 500 miles (800 km) on a single charge back in 2009, and the project got additional support from Asahi Kasei and Central Glass – two companies with decades of experience in materials innovation – who perform simultaneous investigation of several chemistries to increase the chance of project’s success.

IBM Research started the Battery 500 Project to develop lithium-air battery technology that could be used to power a family-sized electric car for approximately 500 miles (800 km) on a single charge back in 2009, and the project got additional support from Asahi Kasei and Central Glass – two companies with decades of experience in materials innovation – who perform simultaneous investigation of several chemistries to increase the chance of project’s success.

Despite the facts that these batteries are much lighter and have greater energy density compared to currently used batteries, there’s the need to make them more stable for everyday use, as well as the need to develop a mass production method which would lower the price of these batteries. A working lab demo of the technology is expected by the end of 2013, and IBM researchers envision that these batteries will be commercially available sometime in the 2020s.

1. ENE-FARM Type S – most efficient residential-use Solid Oxide Fuel Cell

ENE-FARM Type S is a residential-use solid oxide fuel cell (SOFC) co-generation system which utilizes ceramic electrolyte for the power generating cell stack. It generates power through chemical reaction between hydrogen reformed from utility gas and oxygen in the air, and its power generation efficiency is 46.5 percent. The increase of power generation efficiency was achieved with improvements of thermal insulation properties of the modules used in the SOFC system.

ENE-FARM Type S is a residential-use solid oxide fuel cell (SOFC) co-generation system which utilizes ceramic electrolyte for the power generating cell stack. It generates power through chemical reaction between hydrogen reformed from utility gas and oxygen in the air, and its power generation efficiency is 46.5 percent. The increase of power generation efficiency was achieved with improvements of thermal insulation properties of the modules used in the SOFC system.

This high temperature heat is therefore more efficiently used in the process where utility gas is heated at high operating temperatures and reformed to hydrogen. The system can operate continuously and provide roughly 80% of household power consumption. The SOFC system also solves the needs for hot water, since it uses exhausted heat during the power generation process to heat water to approximately 70°C in a 90-litre water storage tank. It also has a built-in back up high efficiency latent heat recovery type boiler that can kick in if the hot-water storage tank is empty.

Leave your response!