Care-O-bot research is going open source

Care-O-bot is a research initiative of German researchers which came to its 3rd iteration. The exciting news is that the folks from the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart are going to give away the platform to other researchers to play with. According to the announcement, a small number of robots will be available to researchers in mid-2010. In addition, the robot will be available for remote use via internet.

Care-O-bot is a research initiative of German researchers which came to its 3rd iteration. The exciting news is that the folks from the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart are going to give away the platform to other researchers to play with. According to the announcement, a small number of robots will be available to researchers in mid-2010. In addition, the robot will be available for remote use via internet.

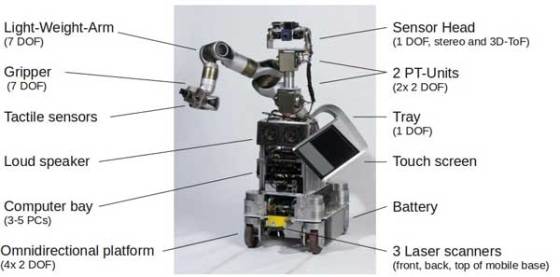

Its dimensions are 75 x 55 x 145cm (30 x 22 x 57 inches) and it weights 180kg (397 pounds). The robot is driven by four wheels which enable it to move up to 1.5 m/s (5ft/s). Each wheel’s orientation and rotational speed can be set individually. This gives the robot an omnidirectional drive enabling advanced movements and simple complete kinematic chain (platform – manipulator – gripper) control. The base also includes the Li-ion battery pack (50 V, 60 Ah), 3 laser scanners and a PC for navigation tasks. The mobile base as modular component thus can be operated independently from the rest of the robot.

The sensor head consists of a high resolution stereo rig and a 3D time-of-flight camera. It is located on a horizontal axis thus allowing the sensor head to move back and forth. This axis is mounted on a 4 DOF manipulator, the torso, giving enough flexibility to position the cameras. The torso can also be used for body gestures as intuitive user feedback.

The Schunk Lightweight Arm 3 (LWA 3) consists of 7 independent rotary modules connected through a common CAN bus and logic and motor power supply. The maximum payload (including the gripper) is about 3-4 kg. Each rotary module contains a position and velocity controller. It is equipped with the Schunk Dextrous Hand (SDH), which offers 7 degrees of freedom and integrated tactile sensors.

Each of the three fingers has two axes, and two fingers can be turned around one vertical axis. Thus different types of grasps can be performed, e.g. cylindrical, spherical, parallel grasps. The single axes and the tactile sensors can be addressed via CAN-Bus or a serial interface. The joints allow position and velocity control and force control can be easily achieved by using the tactile sensor data. The gripper is a modular component that can be easily attached to the manipulator via a fast changer system.

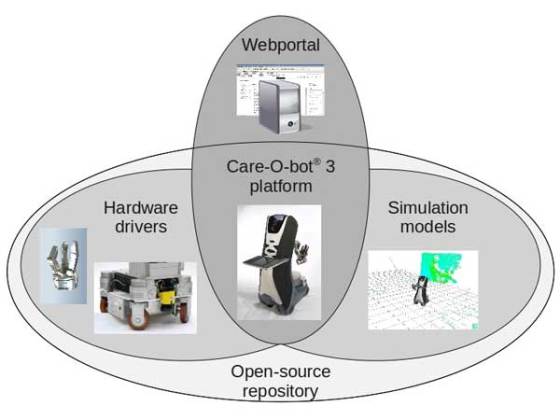

In order to make Care-O-bot 3 available to a larger research community, the Care-O-bot research initiative has been started with the objectives to provide an open source repository for the platform hardware, provide simulation models of hardware components and provide remote access to the Care-O-bot 3 platform hardware. The first two goals have by now been achieved resulting in an open-source repository for different robotic frameworks (specifically ROS and Orocos) that includes all required hardware drivers, simulation models, application examples, and tutorials. The web portal which enables remote access to existing Care-O-bot 3 platforms will be completed soon.

These are very exciting news for those of us who want to work in robotics but don’t have the time or expertise to build our own hardware. Lets hope some big players in robot research as Honda follows the example of other companies and open up their humanoid robot platform or give a few of those for free to research labs around the world.

Leave your response!