Using 3D printers to make octopi-inspired underwater propulsion

Octopods, such as octopuses and squids, are considered to be the most intelligent invertebrates. Their ability to flee fast when in danger by swimming head first inspired researchers at the Fraunhofer Institute to develop a silent propulsion system for boats and water sport devices. The system can be produced at a low cost and in a single step with a 3D printer.

Octopods, such as octopuses and squids, are considered to be the most intelligent invertebrates. Their ability to flee fast when in danger by swimming head first inspired researchers at the Fraunhofer Institute to develop a silent propulsion system for boats and water sport devices. The system can be produced at a low cost and in a single step with a 3D printer.

While they generally move along the ocean floor with their eight arms, they flee by swimming head-first, in line with the principles of propulsion. When the mollusk does this, water is taken into its mantle, which is then closed by contracting sphincter muscles. The water is then squirted back out at a high pressure through a funnel. The resulting propulsion pushes the octopus forward in the opposite direction. By changing the position of the funnel, the octopus can precisely steer its direction of travel.

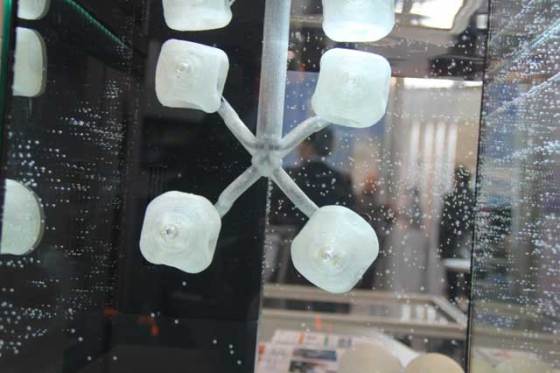

“Squids use this type of movement mainly if they are trying to flee suddenly and quickly. The system is simple, but effective. When they use it, the octopods can speed up considerably over short distances”, said Andreas Fischer, an engineer at Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer IPA). “We have integrated this propulsion principle into our underwater actuators: four elastomer balls with mechanical inner workings create propulsion by pumping water.”

Water is sucked into each actuator or elastomer ball through an opening, while a recirculation valve prevents reflux. A hydraulic piston contracts the integrated cable structure like a muscle. In this way, it pushes the water out of the 20 x 6 cm ball. In turn, a motor pump moves the hydraulic piston.

In order to produce its complex geometry amorphously with soft plastic, the researchers opted for the fused deposition modeling (FDM) generative production process. T processed plastics are heated and liquefied in an extrusion head, where they are transformed into a thin filament in the pressure nozzle. This filament is then applied in layers, from bottom to top, to produce a complex 3D component.

Thanks to FDM, the researchers can also scale the actuators. In fact, components of up to two meters in size can be printed three-dimensionally. This can be done with the help of an industrial robot that has been equipped with three extrusion heads.

“At the moment, the maximum construction volume of FDM facilities is 91.4 x 61 x 91.4 cm, whereby no more than ten different thermoplastics can be processed in layers. With robot-based FDM, much larger components can be produced, with different combinations of material. By integrating continuous filament into thermoplastics, for example, we can manufacture carbon fiber-reinforced components quickly and at a low cost”, said Fisher.

Fischer and his team used thermoplastics such as polyurethane because of their flexibility. The final product of this process is an underwater propulsion system that can stand extreme levels of pressure without breaking. Even in situations of very high stress, it always returns to its original shape.

These properties make this underwater actuator well-suited for maneuvering small boats, or as a floating aid for water sport devices such as jet skis, surf boards, or scooters that pull divers into deep water. In contrast to ship propellers, it is quiet, and fish cannot get caught in it. Fraunhofer researchers claim that production process can be made much shorter by using several robots that work on a single component simultaneously.

Leave your response!