Aluminum studs make solar panels up to 22 percent more efficient

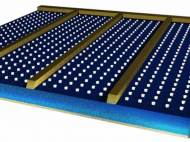

A team of researchers at the Imperial College London and their international collaborators in Belgium, China and Japan have demonstrated that the efficiency of all solar panel designs could be improved by up to 22 percent by covering their surface with aluminum studs that bend and trap light inside the absorbing layer. Solar panels covered with rows of aluminum studs extract more energy from sunlight than those with flat surfaces.

A team of researchers at the Imperial College London and their international collaborators in Belgium, China and Japan have demonstrated that the efficiency of all solar panel designs could be improved by up to 22 percent by covering their surface with aluminum studs that bend and trap light inside the absorbing layer. Solar panels covered with rows of aluminum studs extract more energy from sunlight than those with flat surfaces.

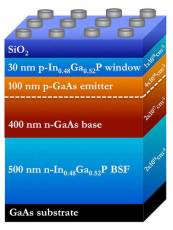

Solar cells that are used in homes and industry are usually made using thick layers of material to absorb sunlight. In order to cut down the cost, many opted for designs with thinner layers, but these designs have limitations because their thinner light-absorbing material extracts less energy.

“In recent years both the efficiency and cost of commercial solar panels have improved but they remain expensive compared to fossil fuels. As the absorbing material alone can make up half the cost of a solar panel our aim has been to reduce to a minimum the amount that is needed”, said Dr Nicholas Hylton, Department of Physics at Imperial College London.

The research team attached rows of aluminum cylinders just 100 nanometers across to the top of the solar panel, where they interact with passing light, causing individual light rays to change course. At the microscopic level, these aluminum studs make the surface of the solar panel look similar to the LEGO building bricks. Aluminum provides significant scattering with minimal absorption over much of the visible spectrum.

The rays of the light are effectively trapped inside the solar cells and travel for longer distances through its absorbing layer. Hence, more energy is extracted from the light.

Many research groups have tried to achieve the light bending effect using silver and gold studs because those materials strongly interact with light. However, both silver and gold actually reduce the efficiency of the solar panels because they absorb some of the light before entering the solar panel.

“The key to understanding these new results is in the way the internal structures of these metals interact with light. Gold and silver both have a strong effect on passing light rays, which can penetrate into the tiny studs and be absorbed, whereas aluminum has a different interaction and merely bends and scatters light as it travels past them into the solar cells”, said Hylton.

According to the Imperial College London researchers, aluminum studs are highly efficient, more affordable, and far more abundant than silver and gold studs. This technology opens up the possibility of making flexible solar panels that could be applied to any flat or curved surface.

For more information, you can read the paper published in the journal Scientific Reports: “Loss mitigation in plasmonic solar cells: aluminium nanoparticles for broadband photocurrent enhancements in GaAs photodiodes” [907KB PDF].

Leave your response!