Biodegradable magnesium alloys as next-gen implants

Scientists at the Korea Institute of Science and Technology (KIST) have succeeded in developing high strength, biodegradable and bioabsorbable Magnesium (Mg), Calcium (Ca) and Zink (Zn) alloys. These alloys have great mechanical properties such as high strength, good tissue compatibility, and medically acceptable corrosion rate. That makes them ideal for next generation of implants used in orthopedics and plastic surgery.

Scientists at the Korea Institute of Science and Technology (KIST) have succeeded in developing high strength, biodegradable and bioabsorbable Magnesium (Mg), Calcium (Ca) and Zink (Zn) alloys. These alloys have great mechanical properties such as high strength, good tissue compatibility, and medically acceptable corrosion rate. That makes them ideal for next generation of implants used in orthopedics and plastic surgery.

Metallic materials such as titanium alloys, cobalt-based alloys as well as stainless steels are often used as load-bearing implants used to repair or replace damaged or diseased tissues. They have high strength, extensibility and are neutral in vivo. Since these alloys remain inside the body after implantation, the downside of their use is the fact they must be surgically removed after the tissue heals sufficiently.

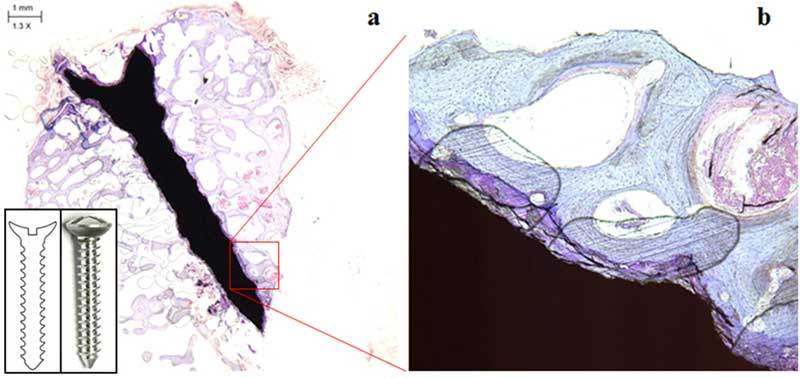

On the other hand, Mg and its alloys remain in the body and maintain mechanical integrity from 12 to 24 weeks after being transplanted into human body. After that period, they decompose and get replaced by natural tissue – thus avoiding additional surgery which leads to potential risk and stress to the patient.

Mg ions are normally present in large amounts in human body and are involved in many biological processes. Mg and its alloys provide both biocompatibility and suitable mechanical properties. What’s more, they may actually have stimulatory effects on the growth of new bone tissue. Although it has been shown that Mg-based alloys can be applied as lightweight, degradable, load-bearing orthopedic implants, they corrode too quickly at physiological pH and degrade swiftly.

In order to overcome the fundamental limitation of Mg-based alloys, the research team developed novel magnesium-based crystalline biomaterials that combine good mechanical properties and medically acceptable corrosion rate. They were matching potentials between the matrix structure of metal and the secondary agents on the matrix structure. Researchers have found the optimal compositions of Mg-Zn-Ca alloys for clinical applications, while maintaining the electrochemical nature of pure metal.

The remarkable achievement was made possible thanks to the Computational Materials Science Laboratory at Kookmin University, which helped to create the effects of synergy between computer simulation and technology.

KIST Biomedical Replacement Team led by Dr. Seok, Hyun-Kwang, also devised biodegradable and bioabsorbable medical devices for use in orthopedics as well as in plastic surgery. Clinical trial conducted by Ajou University Medical Center is currently in progress.

For more information, you can read the article published in the paper Scientific Reports: “Biodegradability engineering of biodegradable Mg alloys: Tailoring the electrochemical properties and microstructure of constituent phases” [4.4MB PDF].

Leave your response!