Building free-standing 3D structures out of liquid metal

Researchers at the North Carolina State University (NC State) have developed a 3D printing technology method which allows them to create free-standing structures made of liquid metal microstructures at room temperature. The researchers developed multiple techniques to create these free-standing microstructures which could be used in electronics, microfluidic networks, tissue engineering scaffolds, photonic band gap structures, and chemical synthesis.

Researchers at the North Carolina State University (NC State) have developed a 3D printing technology method which allows them to create free-standing structures made of liquid metal microstructures at room temperature. The researchers developed multiple techniques to create these free-standing microstructures which could be used in electronics, microfluidic networks, tissue engineering scaffolds, photonic band gap structures, and chemical synthesis.

“It’s difficult to create structures out of liquids, because liquids want to bead up. But we’ve found that a liquid metal alloy of gallium and indium reacts to the oxygen in the air at room temperature to form a ‘skin’ that allows the liquid metal structures to retain their shapes”, said Dr. Michael Dickey, an assistant professor of chemical and biomolecular engineering at NC State.

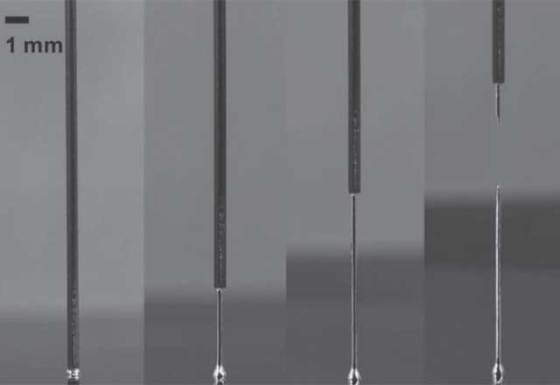

Modest gauge pressure (<5 kPa) applied to a syringe needle extrudes the liquid metal wire onto a substrate controlled by a motorized translation stage. The travel of the translation stage set an upper limit on the length of the wires, which can be several cm long when the wires span from the substrate to the tip of the syringe.

For the wires to form, three things seemingly must happen:

- The oxide skin must yield in tensile mode for the wire to elongate.

- The liquid metal must be under pressure to prevent the liquid from collapsing during elongation.

- The pressure inside the wire cannot be too large otherwise the fiber will bulge in radius.

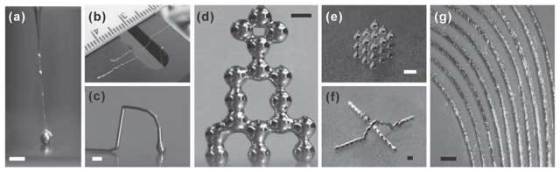

Limited by the upper limit of their length, the length of wires can be determined at any time by applying an appropriate amount of vacuum to the syringe. Once detached from the syringe, the wires maintain their shape. The tallest freestanding wires were approximately 1 cm tall with a diameter of 200 μm.

NC State researchers developed three additional techniques to create free-standing structures from liquid metal. One of the techniques researchers developed involves stacking droplets of liquid metal on top of each other, much like a stack of oranges at the supermarket. The droplets adhere to one another, but retain their shape without merging into a single, larger droplet.

Another technique can be compared to casting, since it requires injection of the liquid metal into a polydimethylsiloxane (PDMS) polymer template which sculpts the metal into a specific shape. PDMS template is then dissolved, leaving the bare, liquid metal in the desired shape.

The last additional technique involves creating wires by rapidly expelling the metal from the syringe using bursts of pressure (~60 kPa of pressure for tens of msec). The fibers naturally form a bead upon hitting the surface, which may be useful for forming contact pads. Without optimization, these fibers have a nearly uniform diameter with some beading along the axis of the fiber. This process can fabricate 3D microstructures of the liquid metal such as wires, arches, and bridges.

Dickey’s team is currently exploring how to further develop these techniques, as well as how to use them in various electronics applications and in conjunction with established 3D printing technologies.

“I’d also like to note that the work by an undergraduate, Collin Ladd, was indispensable to this project”, said Dickey. “He helped develop the concept, and literally created some of this technology out of spare parts he found himself.”

For more information, you can read the paper published in Advanced Materials: “3-D Printing of Free Standing Liquid Metal Microstructures” [903KB PDF].

Leave your response!