Damage-tolerant glass tougher and stronger than steel

After writing about bird-protection glass and blast-resistant glass, here’s an article about glass which is stronger and tougher than steel. A new type of damage-tolerant metallic glass has been developed and tested by a collaboration of researchers with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) and the California Institute of Technology.

After writing about bird-protection glass and blast-resistant glass, here’s an article about glass which is stronger and tougher than steel. A new type of damage-tolerant metallic glass has been developed and tested by a collaboration of researchers with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) and the California Institute of Technology.

“These results mark the first use of a new strategy for metallic glass fabrication and we believe we can use it to make glass that will be even stronger and more tough”, said Robert Ritchie, a materials scientist who led the Berkeley contribution to the research.

Glassy materials have a non-crystalline, amorphous structure that makes them inherently strong but brittle. Whereas the crystalline structure of metals can provide microstructural obstacles that inhibit cracks from propagating, there’s nothing in the amorphous structure of a glass to stop crack propagation. The problem is especially acute in metallic glasses, where single shear bands can form and extend throughout the material leading to failures even at small strains. The new metallic glass is a micro-alloy featuring palladium, a metal with a high “bulk-to-shear” stiffness ratio that counteracts the fragility of glassy materials.

“Because of the high bulk-to-shear modulus ratio of palladium-containing material, the energy needed to form shear bands is much lower than the energy required to turn these shear bands into cracks”, said Ritchie. “The result is that glass undergoes extensive plasticity in response to stress, allowing it to bend rather than crack.”

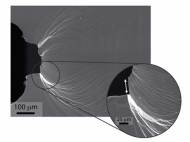

In earlier work, the Berkeley-Caltech collaboration fabricated a metallic glass, dubbed “DH3”, in which the propagation of cracks was blocked by the introduction of a second, crystalline phase of the metal. This crystalline phase, which took the form of dendritic patterns permeating the amorphous structure of the glass, made microstructural barriers to prevent an opened crack from spreading.

In this new work, the collaboration has produced a pure glass material whose unique chemical composition acts to promote extensive plasticity through the formation of multiple shear bands before the bands turn into cracks. The new metallic glass was fabricated by Marios Demetriou at Caltech in the laboratory of William Johnson, one of the pioneers in the field of metallic glass fabrication. Characterization and testing was done at Berkeley Lab by Ritchie’s group.

“Our game now is to try and extend this approach of inducing extensive plasticity prior to fracture to other metallic glasses through changes in composition”, said Ritchie. “The addition of the palladium provides our amorphous material with an unusual capacity for extensive plastic shielding ahead of an opening crack. This promotes a fracture toughness comparable to those of the toughest materials known. The rare combination of toughness and strength, or damage tolerance, extends beyond the benchmark ranges established by the toughest and strongest materials known.”

The initial samples of the new metallic glass were microalloys of palladium with phosphorous, silicon and germanium that yielded glass rods approximately one millimeter in diameter. Adding silver to the mix enabled the Caltech researchers to expand the thickness of the glass rods to six millimeters. The size of the metallic glass is limited by the need to rapidly cool or “quench” the liquid metals for the final amorphous structure.

“Traditionally strength and toughness have been mutually exclusive properties in materials, which makes these new metallic glasses so intellectually exciting,” Ritchie says. “We’re bucking the trend here and pushing the envelope of the damage tolerance that’s accessible to a structural metal.”

For more information, read the paper published in the journal Nature Materials named: “A Damage-Tolerant Glass”.

This will be major breakthrough in Glass and will find wide applications as strong glass.

Dr.A.Jagadeesh Nellore(AP),India