ETFE material research made plastic facades more practicable and affordable

The plastic film of Ethylene tetraflourethylene (ETFE) is a growing trend in architecture these days because it enables new design options. The Eden Project in Southern England, the National Aquatics Center built for swimming events at the Olympics in Beijing and the Allianz Arena in Munich are only three examples of what you can make from these plastic sheets.

The plastic film of Ethylene tetraflourethylene (ETFE) is a growing trend in architecture these days because it enables new design options. The Eden Project in Southern England, the National Aquatics Center built for swimming events at the Olympics in Beijing and the Allianz Arena in Munich are only three examples of what you can make from these plastic sheets.

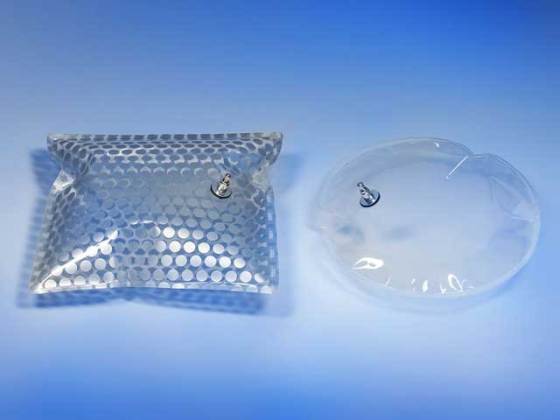

The material can also be used for insulation, as well as temperature and light regulation. In order to become more widely spread, the films will have to be low-cost, easy to process and free of health hazards for them to have a chance in the international construction business. This is the target that six Fraunhofer institutes are working jointly toward in the Multifunctional Membrane Cushion Construction project.

Engineers have been able to use coatings to specifically change the properties of ETFE foils. For example, the amount of light that passes through membranes can be regulated, because membrane cushions with an inner coating of tungsten trioxide turn blue when they come into contact with hydrogen and lose their color if the cushions are filled with oxygen.

“You could use a foil such as this to cover the entire façade of a house and have light pass depending upon sunlight conditions”, said the project coordinator Andreas Kaufmann of the Fraunhofer Institute for Building Physics (IBP).

To date, ETFE membranes have hardly been able to create a heat barrier, but a coat of paper-thin (and therefore transparent) layers of aluminum and paint make sure that heat radiation is effectively reflected. ETFE is coated with Teflon – anti-stick substance you most probably have in one of your frying pans. Because of that, the surface of the foil has to be pretreated chemically before coating. Aside the solution for heat-insulation, the researchers came up with antibacterial layers that inhibit the growth of mold and yeasts.

“We believe that ETFE will emerge as a strong market of its own. The captivating thing about ETFE foil is its transparency combined with its great strength – no other plastic membrane can compete”, said Robert Hodann, the CEO at film manufacturer Nowofol and industrial partner of the research project.

For instance, it will be possible to make LED façades with ETFE foil behind which thousands of light-emitting diodes can be installed. The researchers at Fraunhofer are unveiling new ways to process the film façades at the fair BAU 2011 from January 17 to 22 (stand 131 in Hall C2) in Munich.

Leave your response!