Femtosecond laser creates metal that can defy gravity

In nature, trees pull vast amounts of water from their roots up to their leaves through capillary action, but now scientists at the University of Rochester have created a simple slab of metal that lifts liquid using the same principle – but does so at a speed that would make nature envious. The technology could be used to pump microscopic amounts of liquid around a medical diagnostic chip, cool a computer’s processor, or turn almost any simple metal into an anti-bacterial surface.

In nature, trees pull vast amounts of water from their roots up to their leaves through capillary action, but now scientists at the University of Rochester have created a simple slab of metal that lifts liquid using the same principle – but does so at a speed that would make nature envious. The technology could be used to pump microscopic amounts of liquid around a medical diagnostic chip, cool a computer’s processor, or turn almost any simple metal into an anti-bacterial surface.

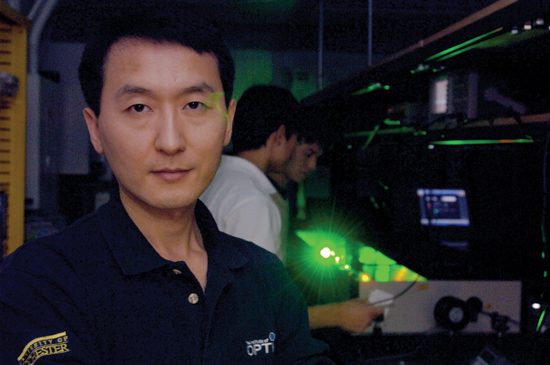

“We’re able to change the surface structure of almost any piece of metal so that we can control how liquid responds to it,” says Chunlei Guo, associate professor of optics at the University of Rochester. “We can even control the direction in which the liquid flows, or whether liquid flows at all.”

In order to do so you need to use an ultra-fast burst of laser light to change the surface of a metal, forming nanoscale and microscale pits, globules, and strands across the metal’s surface. The laser, called a femtosecond laser, produces pulses lasting only a few quadrillionths of a second—a femtosecond is to a second what a second is to about 32 million years. During its brief burst, Guo’s laser unleashes as much power as the entire electric grid of North America does, all focused onto a spot the size of a needlepoint, he says.

The wicking process, which on Guo’s metal moves at a quick one centimeter per second speed against gravity, is very similar to the phenomenon that pulls spilled milk into a paper towel or creates “tears of wine” in a wineglass—molecular attractions and evaporation combine to move a liquid against gravity, says Guo. Likewise, Guo’s nanostructures change the way molecules of a liquid interact with the molecules of the metal, allowing them to become more or less attracted to each other, depending on Guo’s settings.

At a certain size, the metal nanostructures adhere more readily to the liquid’s molecules than the liquid’s molecules adhere to each other, causing the liquid to quickly spread out across the metal. Combined with the effects of evaporation as the liquid spreads, this molecular interaction creates the fast wicking effect in Guo’s metals. Adding laser-etched channels into the metal further enhances Guo’s control of the liquid.

“Imagine a huge waterway system shrunk down onto a tiny chip, like the electronic circuit printed on a microprocessor, so we can perform chemical or biological work with a tiny bit of liquid,” says Guo. “Blood could precisely travel along a certain path to a sensor for disease diagnostics. With such a tiny system, a nurse wouldn’t need to draw a whole tube of blood for a test. A scratch on the skin might contain more than enough cells for a micro-analysis.”

Guo’s team has also created metal that reduces the attraction between water molecules and metal molecules, a phenomenon called hydrophobia. Since germs mostly consist of water, it’s all but impossible for them to grow on a hydrophobic surface, says Guo.

Currently, to alter an area of metal the size of a quarter takes 30 minutes or more, but Guo and his assistant, Anatoliy Vorobyev, are working on refining the technique to make it faster. Fortunately, despite the incredible intensity involved, the femtosecond laser can be powered by a simple wall outlet so once the process gets refined it won’t be hard to use it.

Leave your response!