HITECA high temperature capacitor increases efficiency of electric vehicles

Scientists at the National Physical Laboratory (NPL) have developed a new lead-free, high temperature ceramic capacitor that could improve the efficiency and reliability of electric and hybrid vehicles. Aside having applications in the automobile industry, HITECA capacitors could improve high temperature electronics in the aerospace, power, oil and gas sectors, as well as in high energy applications such as power “pulse”.

Scientists at the National Physical Laboratory (NPL) have developed a new lead-free, high temperature ceramic capacitor that could improve the efficiency and reliability of electric and hybrid vehicles. Aside having applications in the automobile industry, HITECA capacitors could improve high temperature electronics in the aerospace, power, oil and gas sectors, as well as in high energy applications such as power “pulse”.

Hybrid and electric vehicles rely on high efficiency power conversion and management, however the power electronics found in vehicles today require cooling because of limitations in the temperature rating of components such as capacitors, which are used to store electrical energy. Required extra cooling systems add weight to the vehicles and are prone to failures, thus reducing efficiency and reliability.

The Technology Strategy Board program for Low Carbon Vehicles funded scientists at NPL and their collaborators to work on a solution to this problem by developing HITECA – a new ceramic capacitor dielectric material with a high energy density which operates with a stable capacitance at temperatures of 200°C and above.

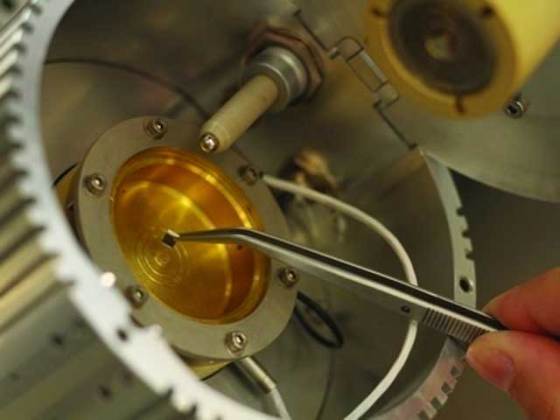

The researchers explored different compositions and different ways of fabricating them. They measured current at a range of high temperatures using advanced measurement techniques. The most promising materials were optimized to achieve the desired properties. The resulting capacitor is created from a ceramic, based on doped-BiFeO3 compound.

Other types of capacitors, for example barium titanate capacitors, can lose up to 85% of their capacitance at working voltage. HITECA also manages to outperform other ceramic chip capacitors in temperature range, lower temperature capacitance change, and lower voltage capacitance change.

“Industrial electronics need to be able to perform in the harsh environments in which they operate. The ability of HITECA capacitors to function at higher temperatures than existing capacitors will help make electronic systems more robust and remove barriers for technologies such as electric vehicles that rely on them”, said Tatiana Correia, who led the work at NPL. “The opportunities for electric vehicles are huge, both financially and environmentally, but they are currently being held back by a few technical issues. With this high temperature capacitor we believe we have solved an important one of those issues and will play a vital part in the move towards mass market electric vehicles.”

The use of this material in electric and hybrid vehicles would reduce the need for cooling and the associated weight of the vehicles. Its high permittivity could enable smaller electronic devices and its reduced loss of capacitance with voltage could improve overall vehicle performance. It could also be used in harsh environments such as space, or for pulsed power where energy is stored over a period of time before being released as a high power ‘pulse’.

For more information, you can read the paper published in journal Applied Physics Letters: “Increasing recoverable energy storage in electroceramic capacitors using “dead-layer” engineering” [924KB PDF].

Leave your response!