Less power consuming and faster plastic electronics

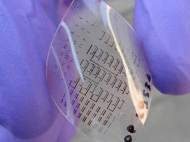

Researchers at the University of Cambridge’s Cavendish Laboratory made a breakthrough for plastic electronic circuits by adding new qualities aside low cost, transparency, flexibility and ease of production – they managed to make them less power consuming and faster. The technology could be used in various applications, ranging from radio frequency identification (RFID) tags on supermarket packaging to transparent displays embedded in vehicle windscreens.

Researchers at the University of Cambridge’s Cavendish Laboratory made a breakthrough for plastic electronic circuits by adding new qualities aside low cost, transparency, flexibility and ease of production – they managed to make them less power consuming and faster. The technology could be used in various applications, ranging from radio frequency identification (RFID) tags on supermarket packaging to transparent displays embedded in vehicle windscreens.

Initially discovered in the late 1970s, plastic electronics allow implementation of flexible and transparent electronics made out of organic materials which can be printed in a small laboratory containing one or two printing tools. However, the full commercial potential of plastic electronic circuits has been hindered by their lower speed and the requirement of high supply voltage (order of 100 V), which meant that they were unable to compete with conventional silicon-based electronics.

Physicists Dr Auke Kronemeijer and Dr Enrico Gili, working in the Cambridge team led by Professor Henning Sirringhaus, have devised a way to fabricate plastic electronic circuits with relatively high performance and much lower power consumption. This was achieved by using new ambipolar organic materials developed by Dr Martin Heeney’s team at Imperial College, London. These materials have carrier mobility in excess of 1 cm2/Vs, and they are capable to conduct both electron and holes – an important ability which makes the use of two different materials for (such as in complementary logic circuits) redundant.

“Our research shows that it’s possible to produce electronic circuits using a new class of ambipolar organic materials that simplify considerably the fabrication process compared with more traditional materials. Typically, to fabricate high performance plastic electronic circuits you need two different active materials. Our technology obtains the same result using only one material”, said Dr Kronemeijer. “This is an ink that can be printed and requires little more than room temperature to reach its peak performance. The robustness and flexibility of our new material opens up the possibility for developing all kinds of intelligent products such as clothing items that interact with their wearer.”

The new circuits developed by Drs Kronemeijer and Gili exhibited the fastest operation published to date using this class of materials (a few hundred KHz) and reduced the power supply requirements by approximately one order of magnitude so that they can already be operated using a standard 9 V battery. University of Cambridge researchers are confident that they will be able to reduce the power supply requirements further to make this technology suitable for ubiquitous electronic devices incorporating printed power supplies.

The integration potential of the new technology will open up possibilities for the production of entirely new products as well as lighter, more flexible versions of existing products. While the technology has the potential to open up a whole new range of exciting applications of plastic electronics which will be cheaper and easier to manufacture, flexible and easy to customize, it is not likely going to replace silicon chips in computational-hungry applications such as PCs.

“Take an item such as a hand held solar powered calculator. This requires several discrete components contained in a bulky casing, such as a solar cell, back-up battery, silicon chip and LCD display. Using plastic electronic technology, all these components could be integrated on a single plastic substrate by simply printing different inks in different areas. Moreover, the end result would be a transparent piece of flexible plastic performing similar operations to the original, bulky calculator”, said Dr Gili. “Although the circuitry may not be powerful enough to perform very complex calculations, this opens up a multitude of novel applications, such as interactive playing cards or self-powered customizable business cards.”

For more information, read the article published in the journal Advanced Materials: “A Selenophene-Based Low-Bandgap Donor–Acceptor Polymer Leading to Fast Ambipolar Logic”.

Leave your response!