New polymer enables cheaper plastic solar cells and electronics

Researchers from Singapore’s Agency for Science, Technology and Research (A*STAR) Institute of Materials Research and Engineering (IMRE) have created a new polymer that can be used in both new age plastic electronics as well as plastic solar cells. The new polymer enables thinner and lighter electronic components and organic solar cells which can be produced with lower costs.

Researchers from Singapore’s Agency for Science, Technology and Research (A*STAR) Institute of Materials Research and Engineering (IMRE) have created a new polymer that can be used in both new age plastic electronics as well as plastic solar cells. The new polymer enables thinner and lighter electronic components and organic solar cells which can be produced with lower costs.

Printed electronics often rely on organic materials like polymers that can be easily processed and manufactured as opposed to traditional electronics which rely on inorganic materials such as copper or silicon. Called POD2T-DTBT, the new polymer consists of polythiophene, benzothiadiazole, and long branched alkyl groups that ensure the polymer has high solubility to facilitate fabrication.

It is capable to produce a high charge mobility of 0.2 cm2/V.s (the same value is achieved by commercially available semiconducting materials), and it also has a high solar power conversion efficiency of 6.3%. These features provide manufacturers with option to lower the costs of production by using just a single bulk resource for making both printed electronics and organic solar cells.

“Current polymers are usually good in one aspect or another, either as a good conductor for use in electronics or endowed with high power conversion efficiency – but not both”, said Dr Chen Zhi Kuan, IMRE Senior Scientist and the lead researcher working on the polymers. “IMRE’s polymer functions not only as a good material to make electronic components, the same material can be used to convert sunlight to electricity efficiently.”

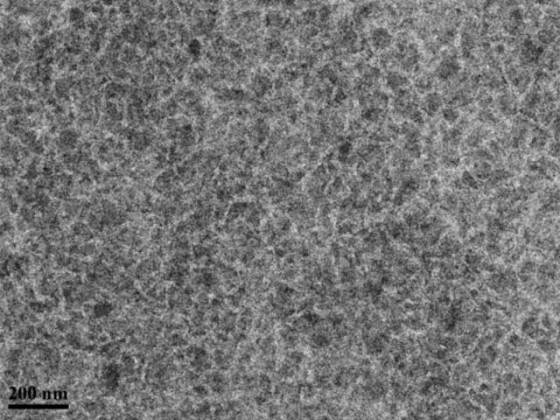

In comparison to A*STAR’s IMRE newly developed polymer, the polymers of the same class such as ones that use thiophene and benzothiadiazole as the building blocks, could achieve only 2.2% power conversion efficiency. Transmission electron microscopy images of the new polymer thin films revealed the presence of two phases – a polymer phase consisting of long fibers and a non-polymeric phase. This morphology enables efficient charge separation and transport, abilities essential for solar cell efficiency.

Similar to the way how newspapers are currently printed, the polymer can be easily applied in roll-to-roll printing techniques which enable manufacture of large area-scale printed electronics and organic solar cells quickly and cheaply. The material could be used in designing new devices where both power harnessing and electronics are needed in a single component. An example of this would be chemical sensors based on organic thin-film transistors and powered by organic solar cells.

The IMRE team is developing other organic materials-based polymers that can be scaled up to production and integrated easily into organic electronics. These materials could be used to make energy harvesting and low-power consumption devices like low-cost organic solar cells, new flexible display devices, next generation smart labels and RFID tags.

For more information, read the article published in the Advanced Materials journal named: “A Versatile Low Bandgap Polymer for Air-Stable, High-Mobility Field-Effect Transistors and Efficient Polymer Solar Cells”.

This is a major advancement, congratulations to researchers from Singapore.

Great Advance in Polymer Technology which will pave the way for cheaper plastic solar cells and may find extensive use in electronics. Of late there is great improvement both in material use and efficiency in solar cells which will help to bring down the cost of solar power generation drastically.

Dr.A.Jagadeesh Nellore(AP),India

Wind Energy Expert

E-mail: anumakonda.jagadeesh@gmail.com