Novel advancements in hydrogels

Hydrogels are gelatinous substances with several biomedical applications, including cartilage repair, implants for minimally invasive surgery and drug delivery. Most hydrogels are weak, brittle, and of low mechanical strength. They also exhibit limited extensibility, recoverability, and poor toughness. On the other hand, double-network hydrogels exhibit high mechanical strength, excellent recoverable properties, and a unique, free-shapeable property.

Hydrogels are gelatinous substances with several biomedical applications, including cartilage repair, implants for minimally invasive surgery and drug delivery. Most hydrogels are weak, brittle, and of low mechanical strength. They also exhibit limited extensibility, recoverability, and poor toughness. On the other hand, double-network hydrogels exhibit high mechanical strength, excellent recoverable properties, and a unique, free-shapeable property.

They are composed of two types of polymer components with opposite physical natures: one rigid and the other flexible. However, double-network hydrogels require complicated methods to be produced and current methods involve multiple-step processes that are complex and time-consuming. Researchers at the University of Akron (UA) simplified the synthesis of double-network hydrogels and also improved the properties of “shape memory hydrogels”.

Novel simplified method to synthesize double-network hydrogels

The research team has developed a simple, efficient and one-pot method to synthesize double-network hydrogels. New method saves time and resources by avoiding a lengthy separation process and purification of the intermediate chemical compounds.

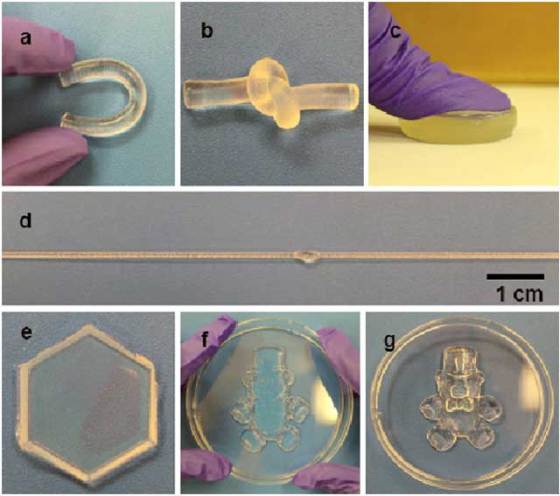

Aside devising a new approach to simplify the production of double-network hydrogels, researchers made these hydrogels tougher. New double-network hydrogels exhibit high mechanical strength, excellent recoverable properties, and a unique, free-shapeable property. These features make them promising substitution for tissues like cartilage, tendon, muscle and blood vessels.

For more information, read the article published in Advanced Materials: “A Robust, One-Pot Synthesis of Highly Mechanical and Recoverable Double-Network Hydrogels Using Thermo-Reversible Sol-Gel Polysaccharide”.

Tougher shape memory hydrogels

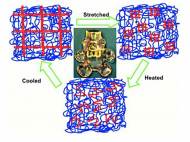

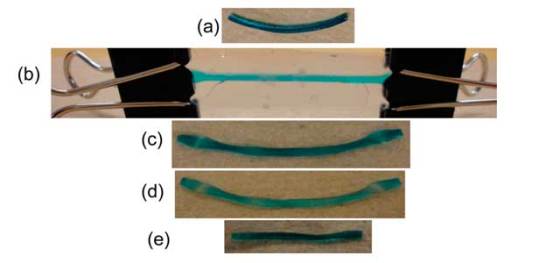

Researchers have synthesized a tougher shape memory hydrogel, which exhibits high mechanical strength, extensibility and fracture toughness. Shape memory polymers are stimuli responsive material that can be bent and stretched, deformed and fixed into a temporary shape. They have the ability to recover their original, permanent shape upon exposure to an external stimulus, such as temperature, light, moisture, or an electric field.

New shape memory hydrogels developed by researchers have physical and covalent cross-links and contain 60 to 70 percent of water. They are thermally actuated, which means that they stretch and change shape when heated, and they retain this temporary shape when cooled.

The microstructure of these hydrogels is composed of glassy hydrophobic nanodomains that behave as multifunctional physical cross-links. The glass transition temperature of the nanodomains is the switching temperature for shape memory. The recovery of the permanent shape can be achieved by reheating the hydrogel to 65°C (149°F).

“Biocompatible, shape memory hydrogels have the potential to be used for minimally invasive surgery and drug delivery. Shape memory may be useful for deployment of hydrogels in biomedical applications using less invasive methods. For example, one can implant a compact form of the device that would deploy into the usable shape after it is implanted”, said Robert Weiss, Hezzleton E. Simmons professor and chair of polymer engineering at the UA.

According to UA researchers, a small form of the shape memory hydrogel could be used to fill a wound or replace tissue. It may be inserted into the body where it could expand into the desired shape of the implant after absorbing bodily fluids. Also, the permeable hydrogels can be used in drug delivery where they can be filled with drugs that release slowly as the gel biodegrades.

For more information about the research related to shape memory hydrogels, you can read the paper published in the ACS Macro Letters: “Mechanically Tough, Thermally Activated Shape Memory Hydrogels” [1.1MB PDF].

Leave your response!