Plastic FIPEL lights could be the next lighting boom

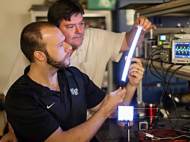

Researchers at Wake Forest University have managed to achieve a significant improvement of lighting based on field-induced polymer electroluminescent (FIPEL) technology. According to its developers, FIPEL lighting provides flicker-free soft white light and it is a shatterproof alternative for large-scale lighting with double efficiency of compact fluorescent (CFL) bulbs and on par efficiency of LED lighting.

Researchers at Wake Forest University have managed to achieve a significant improvement of lighting based on field-induced polymer electroluminescent (FIPEL) technology. According to its developers, FIPEL lighting provides flicker-free soft white light and it is a shatterproof alternative for large-scale lighting with double efficiency of compact fluorescent (CFL) bulbs and on par efficiency of LED lighting.

“People often complain that fluorescent lights bother their eyes, and the hum from the fluorescent tubes irritates anyone sitting at a desk underneath them”, said David Carroll, the scientist leading the development of this technology at Wake Forest. “The new lights we have created can cure both of those problems and more.”

The device is made of three layers of moldable white-emitting polymer blended with a small amount of multi-walled carbon nanotubes (MWNTs) that glow when stimulated with charge. Although it is designed to emit bright and perfectly white light similar to the natural sunlight, it can be made in any color and any shape – from 2×4-foot sheets to replace office lighting to a bulb with Edison sockets to fit household lamps and light fixtures.

Although FIPELs have been around for a while, Carroll’s group is the first to make a large-scale FIPEL that can replace current office lighting and is based on natural white light. FIPELs also are long-lasting – Carroll has one that has worked for about a decade.

The researchers noted that composite devices manage to achieve increase in light emission of five times compared to devices with the pure polymer. They concluded that the use of nanotubes effectively doped the polymer, thus modifying energy level alignment in the device and increasing field-induced polarization currents.

These results may pave the way for widespread use of MWNTs in high-performance FIPEL devices. Aside office and home lighting, Carroll sees potential uses for large display lighting, from store marquees to signs on busses and subway cars, and Wake Forest is working with a company to manufacture the technology and plans to have it ready for consumers as early as next year.

For more information, read the article published in the peer-reviewed journal Organic Electronics: “Effect of multi-walled carbon nanotubes on electron injection and charge generation in AC field-induced polymer electroluminescence”.

Leave your response!