Polymer-metal composite material is able to monitor itself

These days, we normally use sensors to measure whether these components are strained beyond capacity, and it requires a lot of effort to install them into the component parts or glue them onto their surface, and even install networks of sensors with various sensibility. Researchers at Fraunhofer Institute for Manufacturing Technology and Applied Material Research (IFAM) in Bremen, Germany, are developing a new polymer-metal material that has sensory properties makes it possible to produce plastic component parts that monitor themselves.

These days, we normally use sensors to measure whether these components are strained beyond capacity, and it requires a lot of effort to install them into the component parts or glue them onto their surface, and even install networks of sensors with various sensibility. Researchers at Fraunhofer Institute for Manufacturing Technology and Applied Material Research (IFAM) in Bremen, Germany, are developing a new polymer-metal material that has sensory properties makes it possible to produce plastic component parts that monitor themselves.

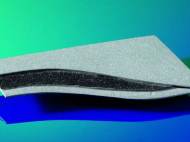

This new composite material is a blend of plastic and metal better known as polymer-metal composite material. There is a wide range of plastics that are suited as a matrix material for manufacturing this composite, which means that it can easily be tailor-made for a whole series of purposes. It is lightweight and conducts current and heat very well due to the high proportion of metal in it. Due to its synthetic character, this material can be easily processed. Furthermore, it can be processed with conventional machines used in plastics manufacturing such as extruders or injection-molding machines in which the heated liquid plastic is injected into a form where it hardens immediately. Finally, this material can be laminated as a type of mat on large surfaces.

This polymer-metal composite material has excellent sensory properties because of its high proportion of metal and a special mixing technique. The metallic filling proportion of the composite material can reach as much as 90 percent when needed. Since the composite‘s electrical resistance changing if there are loads during operation, the signals can be drawn off with cables on the component part and passed onto a measuring instrument for analysis.

It was a special challenge for Arne Haberkorn, the project manager for composite developments at the Fraunhofer Institute for Manufacturing Technology and Applied Material Research, and his colleagues to come up with a technique for evenly processing different metallic substances in liquid plastic. This new technique functions with a whole range of synthetic materials, for instance with polypropylene just as well as with polyamide.

“This means we can combine our polymer-metal composite material with various synthetics and process them into a wide range of component parts. That includes not only solid and heat-resistant, but also soft-flexible workpieces”, said Haberkorn.

Researchers have used various prototypes to demonstrate that the method functions and are now searching for potential industrial users. In the future, researchers want to use nozzles to apply this conducting plastic as a viscous liquid to geometrically complex surfaces. They will be unveiling this polymer-metal composite at the ELECTRONICA 2010 fair (November 9-12 in Munich, Germany).

Leave your response!