Princeton Univeristy researchers developing plastic electronics

A new technique developed by Princeton University engineers for producing electricity-conducting plastics could dramatically lower the cost of manufacturing solar panels. By overcoming technical hurdles to producing plastics that are translucent, malleable and able to conduct electricity, the researchers have opened the door to broader use of the materials in a wide range of electrical devices.

A new technique developed by Princeton University engineers for producing electricity-conducting plastics could dramatically lower the cost of manufacturing solar panels. By overcoming technical hurdles to producing plastics that are translucent, malleable and able to conduct electricity, the researchers have opened the door to broader use of the materials in a wide range of electrical devices.

The area of research, known as “organic electronics” because plastics are carbon-based like living creatures, holds promise for producing new types of electronic devices and new ways of manufacturing existing technologies, but has been hampered by the mysterious loss of conductivity associated with moldable plastics.

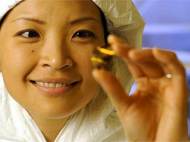

“People didn’t understand what was happening”, said Yueh-Lin Loo, an associate professor of chemical engineering, who led the Princeton team. “We discovered that in making the polymers moldable, their structures are trapped in a rigid form, which prevented electrical current from traveling through them.”

Once they understood the underlying problem, Loo and her colleagues developed a way to relax the structure of the plastics by treating them with an acid after they were molded. By using that method, they were able to make a plastic transistor. They produced the electrodes of the transistor by printing the plastic onto a surface, a fast and cheap method similar to the way an ink-jet printer produces a pattern on a piece of paper.

Loo said the technique potentially could be scaled up for mass production presses akin to those used to print newspapers. “Being able to essentially paint on electronics is a big deal”, Loo said. “You could distribute the plastics in cartridges the way printer ink is sold, and you wouldn’t need exotic machines to print the patterns.”

By allowing plastic solar cells to be manufactured using low-cost printing techniques and by replacing indium tin oxide (ITO) as the primary conducting material, the plastics the team developed hold potential for lowering the cost of solar panels. Currently, the electricity generated by plastic solar cells is collected by a transparent metal conductor made of ITO. The conductor must be transparent so that sunlight can pass through it to the materials in solar cells that absorb the light energy.

A rare and pricey byproduct of mining, ITO had come under increasing demand for use in flat-screen televisions, mobile phones and other devices with display screens. “The cost of indium tin oxide is skyrocketing”, Loo said. “To bring down the costs of plastic solar cells, we need to find a replacement for ITO. Our conducting plastics allow sunlight to pass through them, making them a viable alternative.”

The researchers anticipate that the plastics also could replace expensive metals used in other electronic devices, such as flexible displays. In addition, the scientists are beginning to explore the use of the plastics in biomedical sensors that would display a certain color if a person had an infection. For instance, the plastics turn from yellow to green when exposed to nitric oxide, a chemical compound produced during ear infections in children.

“Imagine tinted windows that can also generate power during the day”, Loo said in the video above. “Imagine disposable sensors that would change color if the water source is contaminated, or yet think of smart plastic patches that can monitor your health and deliver medication when you’re sick. The possibilities are endless.”

author

For more information read the paper published in PNAS named:”Directly patternable, highly conducting polymers for broad applications in organic electronics“.

Great Future.

Dr.A.Jagadeesh Nellore(AP),India