QEE-TECH – mass produced composite materials components

One of goals in transport is to create vehicles with less weight in order to lower their energy consumption. An EPFL spin-off company named EELCEE has developed a process that allows fast fabrication of lightweight composite components in large quantities. Polymer composites offer a good lightweight alternative to metals while offering the strength of steel. In comparison to metal, the composite pieces equivalents achieve weight savings between 20 and 40 percent.

One of goals in transport is to create vehicles with less weight in order to lower their energy consumption. An EPFL spin-off company named EELCEE has developed a process that allows fast fabrication of lightweight composite components in large quantities. Polymer composites offer a good lightweight alternative to metals while offering the strength of steel. In comparison to metal, the composite pieces equivalents achieve weight savings between 20 and 40 percent.

Due to complexity of their production, the application of composite materials laid down in fiber and resin has been limited for Formula 1 racing cars, as well as for high end aeronautics and sailing vessels. The technology involved into manufacture of these parts required a lot of time where the materials and fibers were mixed and molded into the desired shape.

Developed by Jan-Anders Månson and his team in the Laboratory of Composites and Polymers at EPFL, the new technique enables these parts to be mass produced – a feature suitable for application in auto-industry.

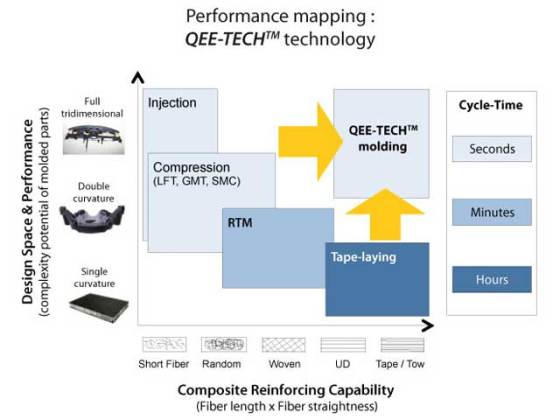

The process could be compared to the mass production process where plastic gains its shape – a process in which a desired mix of materials is pressure-injected into a compressed mold. Named QEE-TECH, the technique merges the reinforcing capabilities of continuous fiber reinforcement with the high-rate complex forming capability of compression molding.

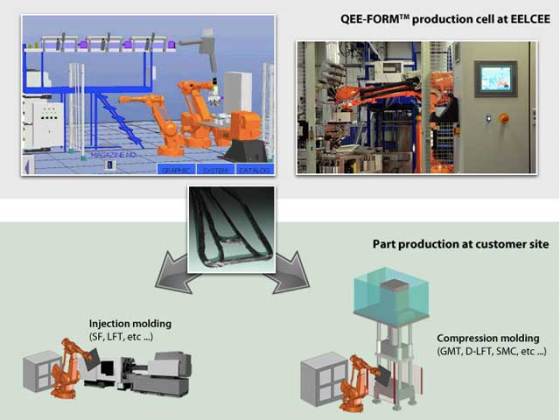

EPFL researchers came up with 36 filament textures (named QEE-FORM) which are manufactured in a fully automated QEE-FORM production cell. The cell uses molds where it combines the desired composite materials and binds them with resin. Once cooled, the mold containing the materials is filled by another layer of resin.

Each QEE-FORM has a different shape, polymer and fiber type, which make them suitable for different mechanical performances and production. QEE-FORM are directly inserted into the forming process where injection molding or compression molding create the final shape of the desired object.

The pressure injection process is pretty fast, and it lowers the need for assembling and welding. Its cycle time of around 1 minute is relatively short, and it allows high annual production without the need for multiple investments into new equipment and molds.

“With this method, the number of parts per year produced by an assembly line is greatly increased and could reach a million, while the costs of production are reduced by 10 percent on average”, said Månson.

The EPFL spin-off EELCEE, based out of the Scientific Park of Ecublens (PSE), is in contact with many suppliers of the large automotive companies, and they hope to see their technology being used to produce structural parts for the automotive industry in 2013.

Aside their primary targeted auto industry, the QEE-TECH technology could find its use in high quality consumer goods which require good structural properties or even in the construction industry where it could offer high structural resistance to high dynamic loads such as earthquakes. It could also lead to structurally sound buildings able to float.

Leave your response!