Self-healing polymer fixes scratches with UV light

A team of researchers in the United States and Switzerland have developed a polymer-based material that can heal itself with the help of UV lighting. Metallo-supramolecular polymers are solid materials capable to become a supple liquid that fills crevasses and gaps left by scrapes and scratches once it is exposed to ultraviolet light for less than a minute after which it re-solidifies.

A team of researchers in the United States and Switzerland have developed a polymer-based material that can heal itself with the help of UV lighting. Metallo-supramolecular polymers are solid materials capable to become a supple liquid that fills crevasses and gaps left by scrapes and scratches once it is exposed to ultraviolet light for less than a minute after which it re-solidifies.

“This is ingenious and transformative materials research”, said Andrew Lovinger, polymers program director in NSF’s Division of Materials Research. “It demonstrates the versatility and power of novel polymeric materials to address technological issues and serve society while creating broadly applicable scientific concepts.”

The new material was created by a mechanism known as supramolecular assembly. Unlike conventional polymers, which consist of long, chain-like molecules with thousands of atoms, these materials are composed of smaller molecules, which are assembled into longer, polymer-like chains using metal ions as “molecular glue” to create the metallo-supramolecular polymers.

“These polymers have a Napoleon Complex”, said Stuart Rowan, the lead researcher and a professor of macromolecular engineering and science and director of the Institute for Advanced Materials at Case Western Reserve University. “In reality they’re pretty small but are designed to behave like they’re big by taking advantage of specific weak molecular interactions.”

While these metallo-supramolecular polymers behave in many ways like normal polymers, when irradiated with intense ultraviolet light the assembled structures become temporarily unglued. This transforms the originally solid material into a liquid that flows easily. When the light is switched off, the material re-assembles and solidifies again and its original properties are restored.

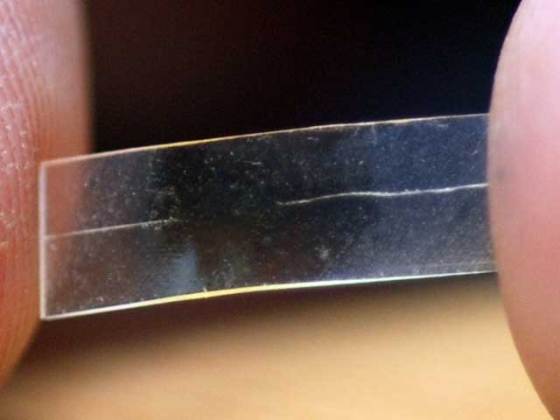

By using lamps such as those dentists use to cure fillings, the researchers managed to repair the scratches in their polymers. Wherever they waved the light beam, the scratches filled up and disappeared, much like a cut that heals and leaves no trace on skin. In addition, unlike the human body, durability of the material does not seem to be compromised by repeated injuries. Tests showed the researchers could repeatedly scratch and heal their materials in the same location.

“Our study is really a fundamental research study”, said Christoph Weder, a professor of polymer chemistry and materials and the director of the Adolphe Merkle Institute. “We tried to create materials that have a unique property matrix, that have unique functionality and that in principle could be very useful.”

The researchers systematically investigated several new polymers to find an optimal combination of mechanical properties and healing ability. They found that metal ions that drive the assembly process via weaker chemical interactions perform better as the light-switchable molecular glue. They also found the materials that assembled in the most orderly microstructures had the best mechanical properties. But, healing efficiency improved as structural order decreased.

The researchers envision widespread uses in the not-so-distant future for re-healable materials like theirs, primarily as coatings for consumer goods such as automobiles, floors and furniture. Although their experiments are only proof of concept and their invention isn’t ready for commercial use, they plan to develop a coating that would be more applicable in an industrial setting.

For more information, you can read the article published in the journal Nature named: “Optically healable supramolecular polymers”.

Leave your response!