SIS solar cells allow creation of colorful solar facades

When you hear someone talking about solar panels, you imagine the black or bluish-gray colored panels. However, various groups of researchers are contributing to changes which help designers and architects in their goal for aesthetics. With the help of thin-film technologies, researchers at the Fraunhofer Institute managed to contribute to this cause by turning solar cells into colorful creations.

When you hear someone talking about solar panels, you imagine the black or bluish-gray colored panels. However, various groups of researchers are contributing to changes which help designers and architects in their goal for aesthetics. With the help of thin-film technologies, researchers at the Fraunhofer Institute managed to contribute to this cause by turning solar cells into colorful creations.

Led by Kevin Füchsel, project manager at the Fraunhofer Institute for Applied Optics and Precision Engineering (Fraunhofer IOF) who has been focusing for the last four years on nanostructured solar cells suitable for mass production, Fraunhofer team and scientists from the Friedrich-Schiller University in Jena are looking for cost-effective techniques and manufacturing processes to increase both the efficiency of solar panels and the design flexibility they give architects and designers.

They are currently working on the fundamentals of how to make colored solar cells from paper-thin silicon wafers. The silicon semiconductor material, just a few micrometers thick, absorbs light and turns it into electricity. In order to increase the efficiency of these panels, lots of light needs to reach the silicon substrate and the semiconductor layer is given an optically neutral protective barrier (insulator). The researchers chose a hundred-nanometer-thick transparent conductive oxide (TCO) layer to guide as many light particles as possible to the semiconductor layer below. Another benefit of TCO is its lower refractive index when compared to silicon, so it works as an anti-reflective coating.

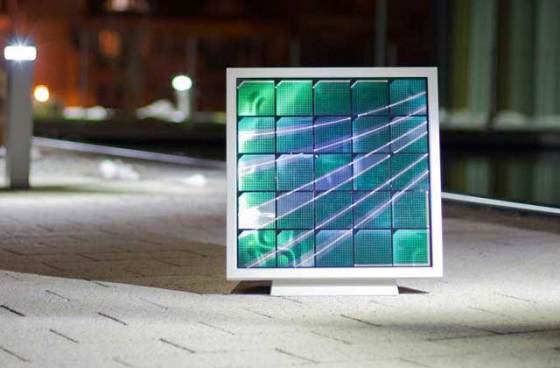

The Jena-based researchers have thus managed to combine wafer-based silicon with processes borrowed from thin-film photovoltaics. Aside capturing more light, the SIS (semiconductor-insulator-semiconductor) solar cell can be made in different colors and shapes. The color comes from changing the physical thickness of the oxide layer, or modifying its refractive index.

According to Fraunhofer researchers, giving solar cells color doesn’t significantly affect their efficiency, but there are restrictions with certain blends of red, blue and green. The additional transparent TCO layer has barely any impact on the current yield, since the simulations showed that SIS cells could be up to 20 percent efficient. In practice, the efficiency depends on the design of the solar panels and the direction the building faces.

Laser-based optical welding process is used to connect several solar cells into a single module. This process enables accurate welding at a micrometer scale and doesn’t damage the surrounding material. Efficient design researchers are also pioneering the use of innovative coating materials, since they are searching for ways to replace expensive indium tin oxide with less expensive zinc oxide with added aluminum.

Fraunhofer researchers are also developing an inkjet printing process to add the conductive TCO later on the silicon wafer. Once developed, this will make manufacturing faster and allow additional degrees of flexibility in design. SIS solar cells could even be used to make large billboards that produce their own electricity.

Hello Mr Damir Beciri, thx for the nice article about our project! We hope we can offer more stuff to report about soon.

Greatings from Germany

Thomas

Hi There. Is it possible to have a single cell tile not only capture the suns energy but also use the energy to give light?

Kindest

author

I didn’t find these particular tiles can be used for such purpose at the moment. However, there are ways to create such a tile with more dense packing of photovoltaics and lighting technologies, and there are combinations where these two technologies are combined to create media walls and interactive facades (you can take a look at an example of a self-sustainable media wall in Beijing).