Unidirectional invisibility cloak for microwaves gets improved

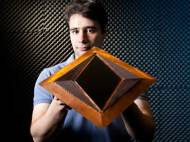

Duke University’s Pratt School of Engineering researchers perfected an old research related to their “invisibility cloak” by incorporating a modification to the device’s design. Although the new design still functions in one plain (it is unidirectional), it solves one of the major flaws of the original device. These new improvements could be used to change the ways of how light or other waves can be controlled or transmitted.

Duke University’s Pratt School of Engineering researchers perfected an old research related to their “invisibility cloak” by incorporating a modification to the device’s design. Although the new design still functions in one plain (it is unidirectional), it solves one of the major flaws of the original device. These new improvements could be used to change the ways of how light or other waves can be controlled or transmitted.

Back in 2006, a team led by scientists at Duke University’s Pratt School of Engineering demonstrated the first working device they named “invisibility cloak”. The cloak deflects microwave beams thanks to meta-materials which are precisely arranged in a series of concentric circles that grant specific electromagnetic properties so they flow around the device with little distortion, thus making any object inside it appear invisible to radars. Meta-materials are man-made materials which have properties that unusual for most of currently known natural materials.

“In order to create the first cloaks, many approximations had to be made in order to fabricate the intricate meta-materials used in the device”, said Nathan Landy, graduate student working in the laboratory of senior investigator David R. Smith, William Bevan Professor of electrical and computer engineering at Duke’s Pratt School of Engineering. “One issue, which we were fully aware of, was loss of the waves due to reflections at the boundaries of the device.”

Structures incorporating meta-materials can be designed to guide electromagnetic waves around an object, only to have them emerge on the other side as if they had passed through an empty volume of space, thereby cloaking the object. The cloak was naturally divided into four quadrants. The “reflections” noted in earlier cloaks tended to occur along the edges and corners of the spaces within and around the meta-material. Test on the previous version of the cloak also shown that a small percentage of the energy in the waves was absorbed, but not enough to effect the overall functioning of the cloak.

Landy was able to reduce the occurrence of these reflections by making a design alteration. The original cloak consisted of parallel and intersecting strips of fiberglass etched with copper. Landy’s cloak used a similar row-by-row design with additional copper strips which enhance the performance of the device.

“Each quadrant of the cloak tended to have voids, or blind spots, at their intersections and corners with each other. After many calculations, we thought we could correct this situation by shifting each strip so that it met its mirror image at each interface”, said Landy. “We built the cloak, and it worked. It split light into two waves which traveled around an object in the center and re-emerged as the single wave minimal loss due to reflections.”

Because the goal of this type of research involves taming light, a new field of transformational optics has emerged. Aside being used in cloaks, similar meta-materials could be used to “smooth out” twists seen in fiber optics by making them seem as straight, thus lessening the level of attenuates (signal amplitude reduction) which occur when a wave is bent.

Pratt School of Engineering researchers are now working to apply the principles learned in the latest experiments to 3D, which poses a much greater challenge compared to current device which works only in one plain.

For more information, read the paper published in the journal Nature Materials: “A full-parameter unidirectional metamaterial cloak for microwaves”.

Leave your response!