Using microwave heating to produce new promising solar cells

The same type of microwave oven technology that most people use to heat up leftover food has found a new application in the solar cell production. Engineers at Oregon State University have for the first time developed a way to use heating from microwave oven to provide a new way to make thin-film photovoltaic products with less energy, expense and impact on the environment.

The same type of microwave oven technology that most people use to heat up leftover food has found a new application in the solar cell production. Engineers at Oregon State University have for the first time developed a way to use heating from microwave oven to provide a new way to make thin-film photovoltaic products with less energy, expense and impact on the environment.

The devised process employs microwave heating in the synthesis of copper zinc tin sulfide – a promising solar cell compound that is less costly and toxic than some other materials used in currently prominent solar cells. With some improvements in the solar efficiency of this fairly new compound in the solar cell production, its use should become very commercially attractive.

“All of the elements used in this new compound are benign and inexpensive, and should have good solar cell performance”, said Gregory Herman, an associate professor in the School of Chemical, Biological and Environmental Engineering at OSU. “Several companies are already moving in this direction as prices continue to rise for some alternative compounds that contain more expensive elements like indium.”

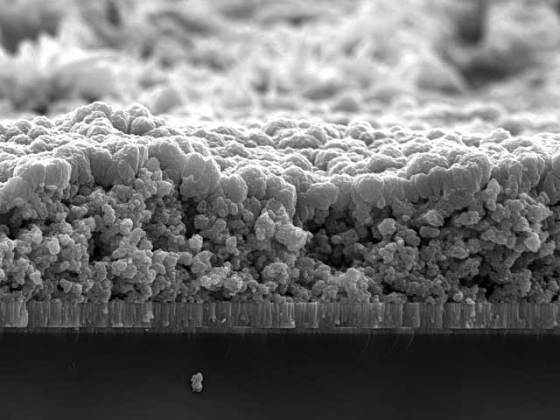

The manufacturing process relies on an approach similar to old-fashioned inkjet printing. An ink composed of nanoparticles is rolled and sprayed onto the base surface. If you used an inkjet printer, you noticed that you need to wait for a few moments before handling the paper, or touching the printed ink because it needed time to dry.

In order to accelerate the “drying” of the printed solar cells, the researchers managed to switch from conventional heating to use of microwave heating. Aside increasing the control over the production process, it also shortened the reaction time of the process, thus increasing fabrication of the photovoltaic device.

The researchers performed tests where they used the new method in order to successfully fabricate a photovoltaic device with usage of nanoparticle inks. This “one-pot” synthesis is fast, cheap and uses far less energy during the production..

“This approach should save money, work well and be easier to scale up at commercial levels, compared to traditional synthetic methods”, said Herman. “Microwave technology offers more precise control over heat and energy to achieve the desired reactions.”

For more information, read the paper published in the journal Physica Status Solidi A: “Microwave assisted synthesis of Cu2ZnSnS4 colloidal nanoparticle inks”.

Many thanks for writing valuable post regarding the subject. I am a fan of your site. Maintain the great work.