Virtual Development and Training-Platform for production facilities

We recently published an article about Canon’s vision of augmented reality which can be used during the design process, and in this article we’re going to write about idea which emerged from cooperation between Fraunhofer Institute and BASF SE who are jointly developing virtual reality (VR) software which could be used to plan and test retrofitting of production facilities during their life cycle.

We recently published an article about Canon’s vision of augmented reality which can be used during the design process, and in this article we’re going to write about idea which emerged from cooperation between Fraunhofer Institute and BASF SE who are jointly developing virtual reality (VR) software which could be used to plan and test retrofitting of production facilities during their life cycle.

With over 110 000 employees, BASF is the world’s largest chemical company. At its headquarters in Ludwigshafen, the company runs over 160 production facilities, two steam crackers, two gas and steam turbine power plants and one sewage treatment plant.

They already employ virtual technologies which aid in interpretation of information and data on every plant in order to help in visualization of the process to the planning engineers, process engineers, assembly coordinators, safety experts and asset managers. A virtual copy of a plant displays every possible view, whether in graphics or figures, in drawings or simulations. This accelerates and improves the planning and implementation of new plans regarding production process or potential retrofits and additions.

Design reviews are an integral part of the planning process – a virtual model for design reviews realistically reproduces every component with the information related to it. The spatial representation makes hidden components or components aligned behind one another easily viewable.

After all, the six-meter high, 360 degree projection surface projects a level of a plant, which is virtually identical to the original. This gives viewers the sensation of standing directly in the plant”, said Sabine Szyler, virtual reality specialist at the Fraunhofer Institute for Factory Operation and Automation IFF.

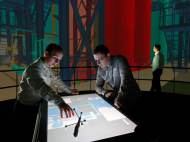

The three-dimensional data from BASF’s planning tools, including the meta data of the plant’s individual components, were exported into the special virtual reality software developed by Fraunhofer IFF researchers – the Virtual Development and Training-Platform. The software provides a preview of the retrofit before it is performed, thus offering improved performance and coordination between plant operators, plant planners and their colleagues, as well as piping contractors, equipment and instrument engineers, steel building contractors or safety supervisors.

“We are so impressed by the design review with virtual reality that we have set up two VR stations in Ludwigshafen. That enables our planning teams there to review designs of other plants any time”, said Axel Franke, Senior Engineering Manager at BASF.

The software can also be used as a virtual interactive learning environment, where it could provide safety training – a top priority in chemical plants. Fraunhofer experts designed a scenario for the retrofit of a nitric acid plant, which enabled the team of operators to inspect and get acquainted with the plant already before its commissioning.

They created a mobile VR training station directly in the control room. The training module presents the complete 3D model of the plant with all of the details such as serial numbers, temperatures, pressures and media as well as training materials available in the presentation. Workers were able to familiarize themselves with the new operation of the plant, identify new access points and learn new safety regulations.

The experts from BASF and the Fraunhofer IFF believe that plant engineers will be unable to operate internationally in the future without virtual technologies, and BASF is increasing their use of virtual technologies in order to maintain their leadership among chemical plant operators.

Leave your response!