Wet-spun graphene oxide flakes create a more robust carbon fiber

Relying on large flakes of graphene oxide that were developed back in 2010 at the Rice University, Rice researchers developed a new carbon fiber with improved strength of its knots. This more robust carbon fiber could be used to increase the strength of many products that use carbon fiber, such as composite materials used in light aircrafts or fabrics for bulletproof apparel.

Relying on large flakes of graphene oxide that were developed back in 2010 at the Rice University, Rice researchers developed a new carbon fiber with improved strength of its knots. This more robust carbon fiber could be used to increase the strength of many products that use carbon fiber, such as composite materials used in light aircrafts or fabrics for bulletproof apparel.

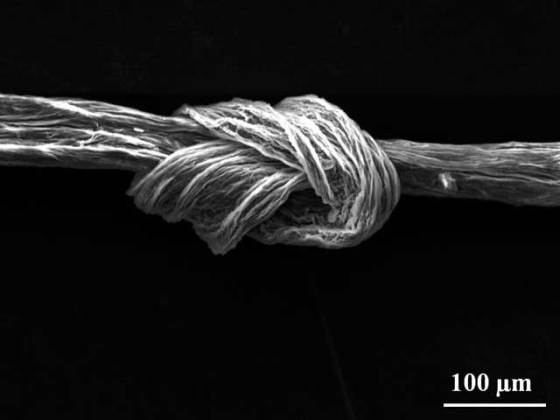

Spun in the lab of chemist James Tour, the carbon fiber demonstrates what the researchers refer to as “100 percent knot efficiency” where the fiber is as likely to break anywhere along its length as at the knot. In comparison, most currently available fibers are most likely to snap under tension at the knot.

“To see this is very strange,” Tour said. “The knot is as strong as any other part of the fiber. That never happens in a carbon fiber or polymer fibers.”

The researchers concluded that the material exhibits this property thanks to graphene oxide flakes created in an environmentally friendly process patented by Rice a few years ago. The flakes are created in a process where they are chemically extracted from graphite, and their average diameter of 22 microns makes them about ten thousand times larger than petroleum-based pitch particles used in current carbon fiber.

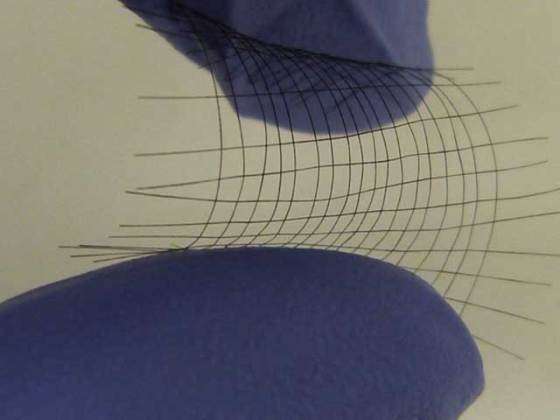

Unlike pitch particles, the atom-thick flakes have an enormous surface area and cling to each other like the scales on a fish when spun into a fiber. Wet-spinning process involves dissolving clumps of raw nanotubes a liquid, followed by squirting of the material through tiny holes to form long strands. Instead using acids or complicated solvents, Rice graduate student Changsheng Xiang managed to perform the process by using water as the solvent.

“Bendability at the knot is due to the fiber’s bending modulus, which is a measure of its flexibility”, said Xiang. “Because graphene oxide has very low bending modulus, it thinks there’s no knot there.”

According to Tour, industrial carbon fibers haven’t improved much in decades because the chemistry involved is approaching its limits. But the new carbon fibers spun at room temperature at Rice already show impressive tensile strength and modulus and have the potential to be even stronger when annealed at higher temperatures.

Xiang added that heating the fibers to the industry standard for making carbon fiber of about 2,100°C (3,812°F) will likely eliminate the knotting strength, but it should greatly improve the material’s tensile strength, which will be good for making novel composite materials.

The Rice researchers also created a second type of fiber using smaller 9-micron flakes of graphene oxide. Unlike the fibers pulled from the larger flakes, these fibers were pulled from the wet-spinning process under tension. The process brought the flakes into even better alignment, resulting in room temperature created fibers with strength nearing commercial products created in far more complicated processes.

For more information, read the paper published in the journal Advanced Materials: “Large Flake Graphene Oxide Fibers with Unconventional 100% Knot Efficiency and Highly Aligned Small Flake Graphene Oxide Fibers”.

Leave your response!